Page 101 - Electromechanical Devices and Components Illustrated Sourcebook

P. 101

Chapter 4 Electrical Controls 63

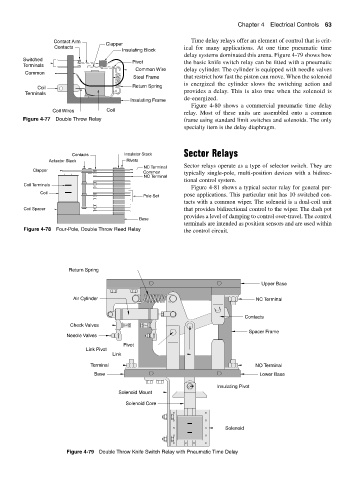

Contact Arm Time delay relays offer an element of control that is crit-

Clapper

Contacts ical for many applications. At one time pneumatic time

Insulating Block

delay systems dominated this arena. Figure 4-79 shows how

Switched

Pivot the basic knife switch relay can be fitted with a pneumatic

Terminals

Common Wire delay cylinder. The cylinder is equipped with needle valves

Common

Steel Frame that restrict how fast the piston can move. When the solenoid

is energized the cylinder slows the switching action and

Coil Return Spring

Terminals provides a delay. This is also true when the solenoid is

de-energized.

Insulating Frame

Figure 4-80 shows a commercial pneumatic time delay

Coil Wires Coil

relay. Most of these units are assembled onto a common

Figure 4-77 Double Throw Relay frame using standard limit switches and solenoids. The only

specialty item is the delay diaphragm.

Sector Relays

Contacts Insulator Stack

Actuator Stack Rivets

Sector relays operate as a type of selector switch. They are

NC Terminal

Clapper

Common typically single-pole, multi-position devices with a bidirec-

NO Terminal

tional control system.

Coil Terminals

Figure 4-81 shows a typical sector relay for general pur-

Coil

Pole Set pose applications. This particular unit has 10 switched con-

tacts with a common wiper. The solenoid is a dual-coil unit

Coil Spacer that provides bidirectional control to the wiper. The dash pot

provides a level of damping to control over-travel. The control

Base

terminals are intended as position sensors and are used within

Figure 4-78 Four-Pole, Double Throw Reed Relay the control circuit.

Return Spring

Upper Base

Air Cylinder NC Terminal

Contacts

Check Valves

Spacer Frame

Needle Valves

Pivot

Link Pivot

Link

Terminal NO Terminal

Base Lower Base

Insulating Pivot

Solenoid Mount

Solenoid Core

Solenoid

Figure 4-79 Double Throw Knife Switch Relay with Pneumatic Time Delay