Page 97 - Electromechanical Devices and Components Illustrated Sourcebook

P. 97

Chapter 4 Electrical Controls 59

On/Off/Auto

Switch

Power

2.5

2.0 3.0

1.5 3.5

1.0 4.0 10 Amp DC

4.5 120 VAC Coil

.5

0 5.0

Seconds

Fault

Input Fuses

Control Emergency

Transformer Stop

115/120 VAC

Enclosure 240/480 VAC

Output Fuse

Pressure Switch

Coil

Terminals

Sensor Loop

MOTOR

STARTER RESET

120 VAC COIL

Motor

Power

(240/480 VAC)

Heater Set

Contactor

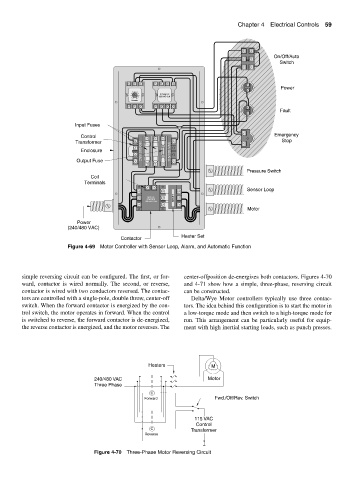

Figure 4-69 Motor Controller with Sensor Loop, Alarm, and Automatic Function

simple reversing circuit can be configured. The first, or for- center-offposition de-energizes both contactors. Figures 4-70

ward, contactor is wired normally. The second, or reverse, and 4-71 show how a simple, three-phase, reversing circuit

contactor is wired with two conductors reversed. The contac- can be constructed.

tors are controlled with a single-pole, double throw, center-off Delta/Wye Motor controllers typically use three contac-

switch. When the forward contactor is energized by the con- tors. The idea behind this configuration is to start the motor in

trol switch, the motor operates in forward. When the control a low-torque mode and then switch to a high-torque mode for

is switched to reverse, the forward contactor is de-energized, run. This arrangement can be particularly useful for equip-

the reverse contactor is energized, and the motor reverses. The ment with high inertial starting loads, such as punch presses.

Heaters M

240/480 VAC Motor

Three Phase

C

Forward Fwd./Off/Rev. Switch

115 VAC

Control

C Transformer

Reverse

Figure 4-70 Three-Phase Motor Reversing Circuit