Page 99 - Electromechanical Devices and Components Illustrated Sourcebook

P. 99

Chapter 4 Electrical Controls 61

Motor Starter

(Main) MOTOR

Power

RESET 220/240 VAC COIL (240/480 VAC)

CONTROLLER

Control

Transformer

460/480 VAC

CONTACTOR

Delta 20 HP / 30 AMP

Contactor 24 VAC COIL On/Off

115/120 VAC

Switch

On/Off

Lamp

CONTACTOR

Wye 20 HP / 30 AMP

Contactor 24 VAC COIL .4 .5 .6

.3 .7

.2 .8

.1 .9

0 1 Chassis Ground

Seconds

Delay On Relay

Enclosure

Internal Panel

Motor

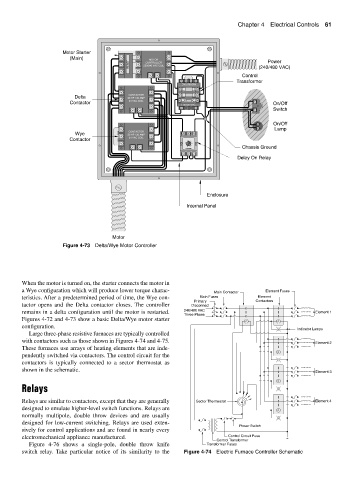

Figure 4-73 Delta/Wye Motor Controller

When the motor is turned on, the starter connects the motor in

a Wye configuration which will produce lower torque charac- Main Contactor Element Fuses

teristics. After a predetermined period of time, the Wye con- Main Fuses Element

Primary Contactors

tactor opens and the Delta contactor closes. The controller Disconnect

remains in a delta configuration until the motor is restarted. 240/480 VAC Element 1

Three Phase

Figures 4-72 and 4-73 show a basic Delta/Wye motor starter

C C

configuration.

L Indicator Lamps

Large three-phase resistive furnaces are typically controlled

with contactors such as those shown in Figures 4-74 and 4-75. Element 2

These furnaces use arrays of heating elements that are inde-

C

pendently switched via contactors. The control circuit for the

contactors is typically connected to a sector thermostat as L

shown in the schematic. Element 3

C

Relays L

Relays are similar to contactors, except that they are generally Sector Thermostat Element 4

designed to emulate higher-level switch functions. Relays are

C

normally multipole, double throw devices and are usually

L

designed for low-current switching. Relays are used exten-

Power Switch

sively for control applications and are found in nearly every

electromechanical appliance manufactured. Control Circuit Fuse

Control Transformer

Figure 4-76 shows a single-pole, double throw knife Transformer Fuses

switch relay. Take particular notice of its similarity to the Figure 4-74 Electric Furnace Controller Schematic