Page 160 - Electromechanical Devices and Components Illustrated Sourcebook

P. 160

122 Electromechanical Devices & Components Illustrated Sourcebook

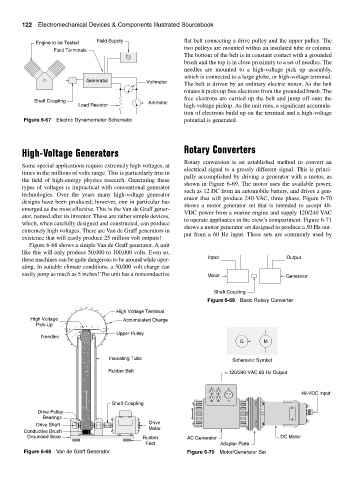

Field Supply flat belt connecting a drive pulley and the upper pulley. The

Engine to be Tested

two pulleys are mounted within an insulated tube or column.

Field Terminals

The bottom of the belt is in constant contact with a grounded

brush and the top is in close proximity to a set of needles. The

needles are mounted to a high-voltage pick up assembly,

which is connected to a large globe, or high-voltage terminal.

Generator Voltmeter

The belt is driven by an ordinary electric motor. As the belt

rotates it picks up free electrons from the grounded brush. The

free electrons are carried up the belt and jump off onto the

Shaft Coupling Ammeter

Load Resistor high-voltage pickup. As the unit runs, a significant accumula-

tion of electrons build up on the terminal and a high-voltage

Figure 6-67 Electric Dynamometer Schematic potential is generated.

High-Voltage Generators Rotary Converters

Rotary conversion is an established method to convert an

Some special applications require extremely high voltages, at

electrical signal to a grossly different signal. This is princi-

times in the millions of volts range. This is particularly true in

pally accomplished by driving a generator with a motor, as

the field of high-energy physics research. Generating these

shown in Figure 6-69. The motor uses the available power,

types of voltages is impractical with conventional generator

such as 12 DC from an automobile battery, and drives a gen-

technologies. Over the years many high-voltage generator

erator that will produce 240 VAC, three phase. Figure 6-70

designs have been produced; however, one in particular has

shows a motor generator set that is intended to accept 48-

emerged as the most effective. This is the Van de Graff gener-

VDC power from a marine engine and supply 120/240 VAC

ator, named after its inventor. These are rather simple devices,

to operate appliances in the crew’s compartment. Figure 6-71

which, when carefully designed and constructed, can produce

shows a motor generator set designed to produce a 50 Hz out-

extremely high voltages. There are Van de Graff generators in

put from a 60 Hz input. These sets are commonly used by

existence that will easily produce 25 million volt outputs!

Figure 6-68 shows a simple Van de Graff generator. A unit

like this will only produce 50,000 to 100,000 volts. Even so,

these machines can be quite dangerous to be around while oper- Input Output

ating. In suitable climate conditions, a 50,000 volt charge can

easily jump as much as 5 inches! The unit has a nonconductive Motor Generator

Shaft Coupling

Figure 6-69 Basic Rotary Converter

- - -

- -

- - High Voltage Terminal

High Voltage - - Accumulated Charge

Pick-Up - - - - - - -

- - - -

- -

- - - - - - - Upper Pulley

Needles - - - - - - - -

- - - - - G M

- -

- - - -- - - -

- - -

- -

- -

- Insulating Tube

- - Schematic Symbol

-

Rubber Belt 120/240-VAC 60 Hz Output

-

-

- 48-VDC Input

-

-

Shaft Coupling

-

Drive Pulley -

Bearings -

-

Drive Shaft - - Drive

Conductive Brush Motor

Grounded Base Rubber AC Generator DC Motor

Feet Adapter Plate

Figure 6-68 Van de Graff Generator Figure 6-70 Motor/Generator Set