Page 155 - Electromechanical Devices and Components Illustrated Sourcebook

P. 155

Chapter 6 Rotating Components 117

Variable Frequency Drives

Actuator Arm

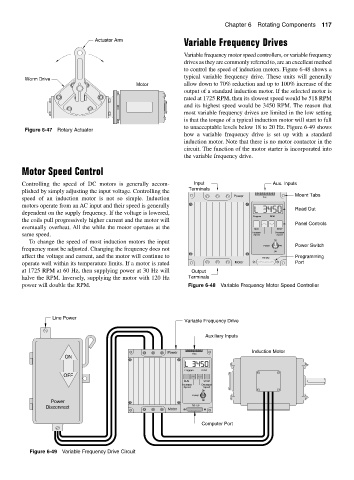

Variable frequency motor speed controllers, or variable frequency

drives as they are commonly referred to, are an excellent method

to control the speed of induction motors. Figure 6-48 shows a

typical variable frequency drive. These units will generally

Worm Drive

Motor allow down to 70% reduction and up to 100% increase of the

output of a standard induction motor. If the selected motor is

rated at 1725 RPM, then its slowest speed would be 518 RPM

and its highest speed would be 3450 RPM. The reason that

most variable frequency drives are limited in the low setting

is that the torque of a typical induction motor will start to fall

to unacceptable levels below 18 to 20 Hz. Figure 6-49 shows

Figure 6-47 Rotary Actuator

how a variable frequency drive is set up with a standard

induction motor. Note that there is no motor contactor in the

circuit. The function of the motor starter is incorporated into

the variable frequency drive.

Motor Speed Control

Controlling the speed of DC motors is generally accom- Input Aux. Inputs

plished by simply adjusting the input voltage. Controlling the Terminals Mount Tabs

speed of an induction motor is not so simple. Induction Power Aux.

motors operate from an AC input and their speed is generally

Read Out

dependent on the supply frequency. If the voltage is lowered,

Program RPM

the coils pull progressively higher current and the motor will

Panel Controls

eventually overheat. All the while the motor operates at the RUN STOP

same speed. Increase Decrease

Speed

Speed

To change the speed of most induction motors the input On

Power Power Switch

frequency must be adjusted. Changing the frequency does not

Off

affect the voltage and current, and the motor will continue to RS-232 Programming

operate well within its temperature limits. If a motor is rated Motor Port

at 1725 RPM at 60 Hz, then supplying power at 30 Hz will Output

halve the RPM. Inversely, supplying the motor with 120 Hz Terminals

power will double the RPM. Figure 6-48 Variable Frequency Motor Speed Controller

Line Power

Variable Frequency Drive

Auxiliary Inputs

Power Aux. Induction Motor

ON

Program RPM

OFF

RUN STOP

Increase Decrease

Speed Speed

On

Power

Power Off

Disconnect Motor RS-232

Computer Port

Figure 6-49 Variable Frequency Drive Circuit