Page 154 - Electromechanical Devices and Components Illustrated Sourcebook

P. 154

116 Electromechanical Devices & Components Illustrated Sourcebook

Translating Rotary Motion Guide Bearing Preload Spring

Antibacklash Element

Drive Nut

to Linear Motion Lead Screw

Motion control most often means controlling linear motion.

Since motors produce rotary motion, some sort of linear

conversion must take place. The most common method is to

couple the output of the motor to a threaded shaft, or lead

screw.

For high load applications, recirculating ball screws are

usually used. The nuts used in these types of screws use ball

Tooth Belt

bearings to engage the threads. The balls are free to rotate and End Plates

are fed back into the front of the nut via an external conduit Guide Rods Motor Shaft

as they roll out of the back. In this way a threaded shaft and

nut can be produced with minimal friction and, therefore, Motor Mount

minimal wear. These types of screws are commonly found in Stepper Motor

computer controlled machine tools. Figure 6-43 shows a pow-

Figure 6-45 Rotating Antibacklash Nut

ered recirculating ball screw with a fixed nut.

Clamp Collar

Recirculating Ball Nut

Shaft Coupling Switching the motor to forward or reverse either extends or

Bearing Ball retracts the actuator.

Moving Table Screw

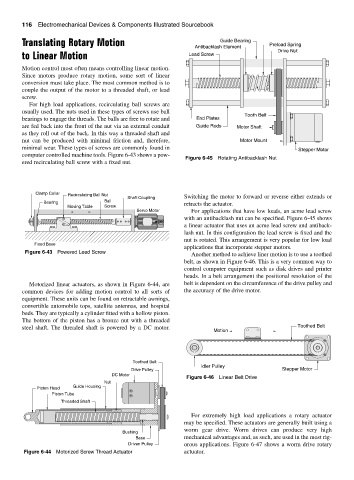

Servo Motor For applications that have low loads, an acme lead screw

with an antibacklash nut can be specified. Figure 6-45 shows

a linear actuator that uses an acme lead screw and antiback-

lash nut. In this configuration the lead screw is fixed and the

nut is rotated. This arrangement is very popular for low load

Fixed Base

applications that incorporate stepper motors.

Figure 6-43 Powered Lead Screw

Another method to achieve liner motion is to use a toothed

belt, as shown in Figure 6-46. This is a very common way to

control computer equipment such as disk drives and printer

heads. In a belt arrangement the positional resolution of the

Motorized linear actuators, as shown in Figure 6-44, are belt is dependent on the circumference of the drive pulley and

common devices for adding motion control to all sorts of the accuracy of the drive motor.

equipment. These units can be found on retractable awnings,

convertible automobile tops, satellite antennas, and hospital

beds. They are typically a cylinder fitted with a hollow piston.

The bottom of the piston has a bronze nut with a threaded

steel shaft. The threaded shaft is powered by a DC motor. Toothed Belt

Motion

Toothed Belt

Idler Pulley

Drive Pulley Stepper Motor

DC Motor

Figure 6-46 Linear Belt Drive

Nut

Guide Housing

Piston Head

Piston Tube

Threaded Shaft

For extremely high load applications a rotary actuator

may be specified. These actuators are generally built using a

worm gear drive. Worm drives can produce very high

Bushing

Base mechanical advantages and, as such, are used in the most rig-

Driven Pulley orous applications. Figure 6-47 shows a worm drive rotary

Figure 6-44 Motorized Screw Thread Actuator actuator.