Page 156 - Electromechanical Devices and Components Illustrated Sourcebook

P. 156

118 Electromechanical Devices & Components Illustrated Sourcebook

Another function that variable frequency drives can pro- Delay Time

vide is soft starting. Soft starting is useful for applications that Zero Crossing On Time

have high inertial loads, such as heavy flywheels and cable

spools. If a motor is exposed to an excessively long start cycle

it may overheat and can be severely damaged. By starting a

motor at a lower RPM, the starting load may be mitigated. Start Ramp Up Run

Figure 6-50 shows the progression of a variable frequency Figure 6-52 Soft Starter Switching Cycle

drive during a soft start cycle.

SCR Controllers

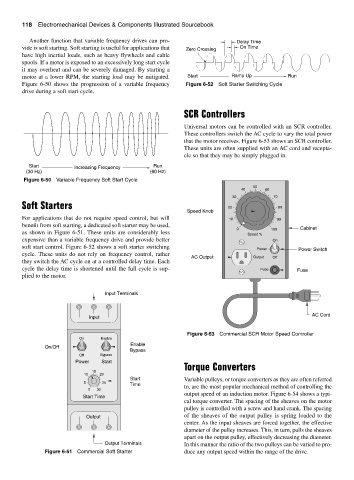

Universal motors can be controlled with an SCR controller.

These controllers switch the AC cycle to vary the total power

that the motor receives. Figure 6-53 shows an SCR controller.

These units are often supplied with an AC cord and recepta-

cle so that they may be simply plugged in.

Start Increasing Frequency Run

(30 Hz) (60 Hz)

Figure 6-50 Variable Frequency Soft Start Cycle

50

40 60

30 70

Soft Starters 20 80

Speed Knob

For applications that do not require speed control, but will 10 90

benefit from soft starting, a dedicated soft starter may be used,

0 100 Cabinet

as shown in Figure 6-51. These units are considerably less Speed %

expensive than a variable frequency drive and provide better On

soft start control. Figure 6-52 shows a soft starter switching Power Power Switch

cycle. These units do not rely on frequency control, rather

AC Output Output Off

they switch the AC cycle on at a controlled delay time. Each

cycle the delay time is shortened until the full cycle is sup- Fuse Fuse

plied to the motor.

Input Terminals

AC Cord

Input

Figure 6-53 Commercial SCR Motor Speed Controller

On Enable

Enable

On/Off

Bypass

Off Bypass

Power Start

Torque Converters

15

10 20

Start Variable pulleys, or torque converters as they are often referred

5 25 Time

0 30 to, are the most popular mechanical method of controlling the

output speed of an induction motor. Figure 6-54 shows a typi-

Start Time

cal torque converter. The spacing of the sheaves on the motor

pulley is controlled with a screw and hand crank. The spacing

Output of the sheaves of the output pulley is spring loaded to the

center. As the input sheaves are forced together, the effective

diameter of the pulley increases. This, in turn, pulls the sheaves

apart on the output pulley, effectively decreasing the diameter.

Output Terminals In this manner the ratio of the two pulleys can be varied to pro-

Figure 6-51 Commercial Soft Starter duce any output speed within the range of the drive.