Page 88 - Engineered Interfaces in Fiber Reinforced Composites

P. 88

Chapter 3. Measurements of" interfacelinterlaminar properties 71

3.3.6. Rail shear test

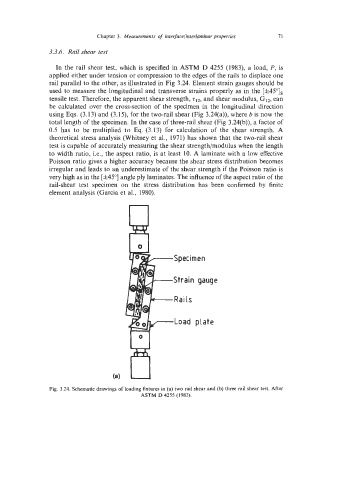

In the rail shear test, which is specified in ASTM D 4255 (1983), a load, P, is

applied either under tension or compression to the edges of the rails to displace one

rail parallel to the other, as illustrated in Fig 3.24. Element strain gauges should be

used to measure the longitudinal and transverse strains properly as in the [f45"Is

tensile test. Therefore, the apparent shear strength, rI2, and shear modulus, G12, can

be calculated over the cross-section of the specimen in the longitudinal direction

using Eqs. (3.13) and (3.15), for the two-rail shear (Fig 3.24(a)), where b is now the

total length of the specimen. In the case of three-rail shear (Fig 3.24(b)), a factor of

0.5 has to be multiplied to Eq. (3.13) for calculation of the shear strength. A

theoretical stress analysis (Whitney et al., 1971) has shown that the two-rail shear

test is capable of accurately measuring the shear strength/modulus when the length

to width ratio, Le., the aspect ratio, is at least 10. A laminate with a low effective

Poisson ratio gives a higher accuracy because the shear stress distribution becomes

irregular and leads to an underestimate of the shear strength if the Poisson ratio is

very high as in the [f45"] angle ply laminates. The influence of the aspect ratio of the

rail-shear test specimen on the stress distribution has been confirmed by finite

element analysis (Garcia et al., 1980).

Specimen

Strain gauge

Rails

Load plate

Fig. 3.24. Schematic drawings of loading fixtures in (a) two rail shear and (b) three rail shear test. After

ASTM D 4255 (1983).