Page 90 - Engineered Interfaces in Fiber Reinforced Composites

P. 90

Chapter 3. Measurements of interfacelinterlaminar properties 73

-

2.54 to 6.60 6.4

1 4 k363 -

7 to 1,65 -Ib

1,02

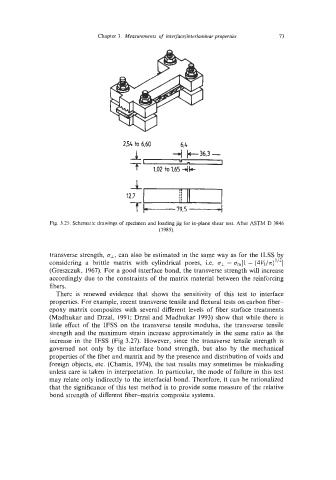

Fig. 3.25. Schematic drawings of specimen and loading jig for in-plane shear test. After ASTM D 3846

(1985).

~ also be estimated in the same way as for the ILSS b

transverse strength, r ~ can ,

considering a brittle matrix with cylindrical pores, i.e, oI = om[l - (4J4/n) I/? ]

(Greszczuk, 1967). For a good interface bond, the transverse strength will increase

accordingly due to the constraints of the matrix material between the reinforcing

fibers.

There is renewed evidence that shows the sensitivity of this test to interface

properties. For example, recent transverse tensile and flexural tests on carbon fiber-

epoxy matrix composites with several different levels of fiber surface treatments

(Madhukar and Drzal, 1991; Drzal and Madhukar 1993) show that while there is

little effect of the IFSS on the transverse tensile modulus, the transverse tensile

strength and the maximum strain increase approximately in the same ratio as the

increase in the IFSS (Fig 3.27). However, since the transverse tensile strength is

governed not only by the interface bond strength, but also by the mechanical

properties of the fiber and matrix and by the presence and distribution of voids and

foreign objects, etc. (Chamis, 1974), the test results may sometimes be misleading

unless care is taken in interpretation. In particular, the mode of failure in this test

may relate only indirectly to the interfacial bond. Therefore, it can be rationalized

that the significance of this test method is to provide some measure of the relative

bond strength of different fiber-matrix composite systems.