Page 89 - Engineered Interfaces in Fiber Reinforced Composites

P. 89

72 Engineered interfaces in jber reinforced composites

load

-Specimen

-Strain

gauges

1

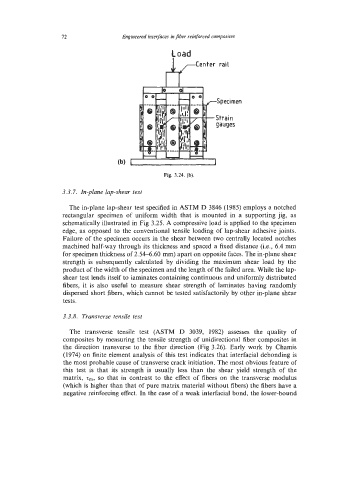

Fig. 3.24. (b).

3.3.7. In-plane lap-shear test

The in-plane lap-shear test specified in ASTM D 3846 (1985) employs a notched

rectangular specimen of uniform width that is mounted in a supporting jig, as

schematically illustrated in Fig 3.25. A compressive load is applied to the specimen

edge, as opposed to the conventional tensile loading of lap-shear adhesive joints.

Failure of the specimen occurs in the shear between two centrally located notches

machined half-way through its thickness and spaced a fixed distance (Le., 6.4 mm

for specimen thickness of 2.54-6.60 mm) apart on opposite faces. The in-plane shear

strength is subsequently calculated by dividing the maximum shear load by the

product of the width of the specimen and the length of the failed area. While the lap-

shear test lends itself to laminates containing continuous and uniformly distributed

fibers, it is also useful to measure shear strength of laminates having randomly

dispersed short fibers, which cannot be tested satisfactorily by other in-plane shear

tests.

3.3.8. Transverse tensile test

The transverse tensile test (ASTM D 3039, 1982) assesses the quality of

composites by measuring the tensile strength of unidirectional fiber composites in

the direction transverse to the fiber direction (Fig 3.26). Early work by Chamis

(1974) on finite element analysis of this test indicates that interfacial debonding is

the most probable cause of transverse crack initiation. The most obvious feature of

this test is that its strength is usually less than the shear yield strength of the

matrix, z,, so that in contrast to the effect of fibers on the transverse modulus

(which is higher than that of pure matrix material without fibers) the fibers have a

negative reinforcing effect. In the case of a weak interfacial bond, the lower-bound