Page 339 - Engineering Plastics Handbook

P. 339

Polyarylethersulfones (PAES) 297

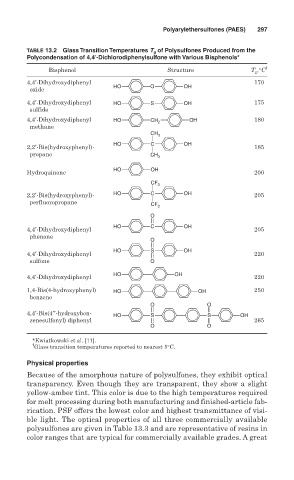

TABLE 13.2 Glass Transition Temperatures T g of Polysulfones Produced from the

Polycondensation of 4,4′-Dichlorodiphenylsulfone with Various Bisphenols*

Bisphenol Structure T g ,°C †

4,4′-Dihydroxydiphenyl 170

HO O OH

oxide

4,4′-Dihydroxydiphenyl HO S OH 175

sulfide

4,4′-Dihydroxydiphenyl HO CH 2 OH 180

methane

CH

3

HO C OH

2,2′-Bis(hydroxyphenyl)- 185

propane CH

3

HO OH

Hydroquinone 200

CF 3

2,2′-Bis(hydroxyphenyl)- HO C OH 205

perfluoropropane CF 3

O

HO C OH

4,4′-Dihydroxydiphenyl 205

phenone

O

HO S OH

4,4′-Dihydroxydiphenyl 220

sulfone O

HO OH

4,4′-Dihydroxydiphenyl 220

1,4-Bis(4-hydroxyphenyl) HO OH 250

benzene

O O

4,4′-Bis(4′′-hydroxyben-

HO S S OH

zenesulfonyl) diphenyl 265

O O

*Kwiatkowski et al. [11].

†

Glass transition temperatures reported to nearest 5°C.

Physical properties

Because of the amorphous nature of polysulfones, they exhibit optical

transparency. Even though they are transparent, they show a slight

yellow-amber tint. This color is due to the high temperatures required

for melt processing during both manufacturing and finished-article fab-

rication. PSF offers the lowest color and highest transmittance of visi-

ble light. The optical properties of all three commercially available

polysulfones are given in Table 13.3 and are representative of resins in

color ranges that are typical for commercially available grades. A great