Page 400 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 400

Extrude and Revolve Features Engineering Design with SOLIDWORKS® 2018

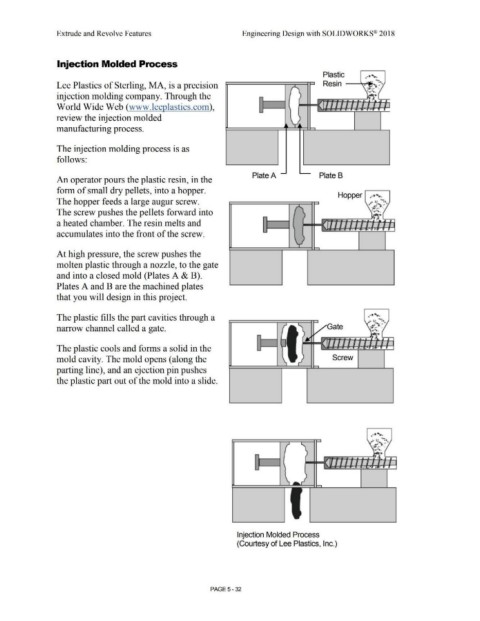

Injection Molded Process

Plastic .. , ... _

Lee Plastics of Sterling, MA, is a precision µ Resin -~'\'"'""· · ·: .... : '·

.-· •.

";,,,' ..... .

J,,.

·"<°",

injection molding company. Through the - I , ~.

)

World Wide Web (www.leeplastics.com),

- • •

review the injection molded

manufacturing process.

The injection molding process is as

follows:

Plate A - Plate B

An operator pours the plastic resin, in the

form of small dry pellets, into a hopper.

Hopper • ·•'·

-

•

The hopper feeds a large augur screw. µ ~ ,.... . .. •

~· . ...

•

, . -~ ,

..I...

..,.._

The screw pushes the pellets forward into ... ', -·

a heated chamber. The resin melts and I •• l ·~ ,i_

•

... • . . ' ~ - -- • 1 •• I

accumulates into the front of the screw.

y>

-

At high pressure, the screw pushes the

molten plastic through a nozzle, to the gate

and into a closed mold (Plates A & B).

Plates A and Bare the machined plates

that you will design in this project.

. ... --..

The plastic fills the part cavities through a Jt \ • -

••

.. =-... .. .

.-...

narrow channel called a gate. ;>,I'... . .

••

The plastic cools and forms a solid in the •

mold cavity. The mold opens ( along the Screw

parting line), and an ejection pin pushes

the plastic part out of the mold into a slide.

..~ ...

• -

:"' ...

~ t..· ....

•• •

. .

-·· .

Injection Molded Process

(Courtesy of Lee Plastics, Inc.)

PAGE5 - 32