Page 438 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 438

Extrude and Revolve Features Engineering Design with SOLIDWORKS® 2018

Design Checklist and Goals before Plastic Manufacturing

The BATTERYPLATE part is manufactured from a plastic resin. A plastic part requires

mold base plates, named Plate A and Plate B, to create the mold. A plastic part also

requires knowledge of the material and manufacturing process. Critical decisions need to

be made. What type of plastic resin do you use? The answer is derived from the

development team: designer, resin supplier, mold maker and mold base, (Plate A & Plate

B) supplier.

Ticona (www.ticona.com) supplies their customers with a designer's checklist to assist

the designer in selecting the correct material.

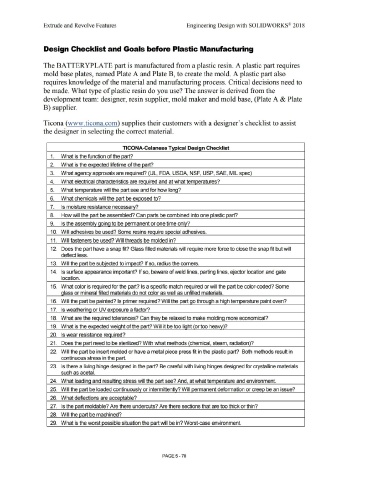

TICONA-Celanese T·.":}ical Desian Checklist

1 . What is the function of the part?

2. What is the exoected lifetime of the oart?

3. What agency approvals are required? (UL, FDA, USDA, NSF, USP, SAE, MIL spec)

4. What electrical characteristics are reauired and at what temperatures?

5. What temoerature will the oart see and for how Iona?

6. What chemicals will the oart be exoosed to?

7. Is moisture resistance necessarv?

8. How will the oart be assembled? Can oarts be combined into one olastic oart?

9. Is the assembly aoina to be permanent or one time only?

10. Will adhesives be used? Some resins reauire soecial adhesives.

11. Will fasteners be used? Will threads be molded in?

12. Does the part have a snap fit? Glass filled materials will require more force to close the snap fit but will

deflect less.

13. Will the oart be subjected to imoact? If so, radius the corners.

14. Is surface appearance important? If so, beware of weld lines, parting lines, ejector location and gate

location.

15. What color is required for the part? Is a specific match required or will the part be color-coded? Some

alass or mineral filled materials do not color as well as unfilled materials.

16. Will the part be painted? Is primer required? Will the part ao throuah a hiah temperature paint oven?

17. Is weatherina or UV exposure a factor?

18. What are the reauired tolerances? Can they be relaxed to make moldinq more economical?

19. What is the expected weiaht of the part? Will it be too liaht , or too heaw ?

20. Is wear resistance reauired?

21. Does the part need to be sterilized? With what methods (chemical, steam, radiation)?

22. Will the part be insert molded or have a metal piece press fit in the plastic part? Both methods result in

continuous stress in the part.

23. Is there a living hinge designed in the part? Be careful with living hinges designed for crystalline materials

such as acetal.

24. What loadina and resultina stress will the part see? And, at what temperature and environment.

25. Will the oart be loaded continuouslv or intermittently? Will oermanent deformation or creeo be an issue?

26. What deflections are acceotable?

27. Is the part moldable? Are there undercuts? Are there sections that are too thick or thin?

28. Will the oart be machined?

29. What is the worst possible situation the part will be in? Worst-case environment.

PAGE5-70