Page 463 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 463

Engineering Design with SOLIDWORKS® 2018 Extrude and Revolve Features

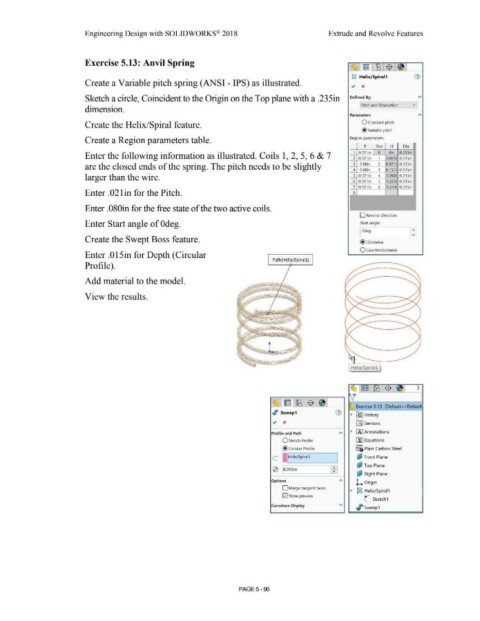

Exercise 5.13: Anvil Spring

(3, ~ - [t8 $ ~

18 Helix/ Spiral 1 G)

Create a Variable pitch spring (ANSI - IPS) as illustrated. ~ x

Sketch a circle, Coincident to the Origin on the Top plane with a .235in Defined By: A

[ Pitch and Revolution v

dimension.

Parameters A

Create the Helix/Spiral feature. O Constant pitch

@ variable pitch

Create a Region parameters table. Region parameters:

p Rev H Dia n

Oin

0.235in

Enter the following information as illustrated. Coils 1, 2, 5, 6 & 7 1 O 021 in 0 0.021 i 0.235in

2 0.021 in

1

are the closed ends of the spring. The pitch needs to be slightly 3 0.08in 2 0.0715 0.235in

4 0.08in 3 0.1515 0.235in

larger than the wire. 5 0.021 in 4 0.202i 0.235in

6 0.021 in 5 0.223i 0.235in

7 0.021 in 6 0.244i 0.235in

Enter . 021 in for the Pitch. 8

Enter .080in for the free state of the two active coils.

D Reverse direction

Enter Start angle of Odeg. Start angle:

1:

I Odeg

Create the Swept Boss feature. @ Clockwise

O Counterclockwise

Enter .015in for Depth (Circular

P ath(HeliX/Spirall )

Profile).

Add material to the model.

View the results.

Helix/Spirall

>

~ El ~ $ ~ Exercise 5.13 (Default< <Defaul

-

-

,r Sweep1 G)

~ ~ I History

~ x l'.0:] Sensors

Profile and Path A ~ IA) Annotations

O Sketch Profile ~ Equations

o-

@ Circular Profile ~::a Plain Carbon Steel

c I IHeliX/Spiral1 I Qi Front Plane

0 ;o.015in ffi: O,J Top Plane

ci.' Right Plane

Options A

L Origin

.-

D Merge tangent faces

... ~ Helix/ Spiral1

0 Show preview

L Sketch1

Curvature Display v

Jf sw eep1

PAGE5 - 95