Page 268 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 268

HEAT TRANSFER, INSULATION, AND FREEZE PROTECTION

5.52 CHAPTER FIVE

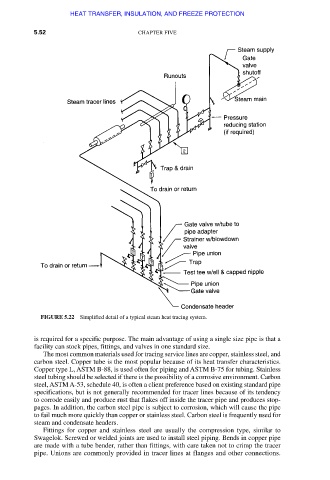

FIGURE 5.22 Simplified detail of a typical steam heat tracing system.

is required for a specific purpose. The main advantage of using a single size pipe is that a

facility can stock pipes, fittings, and valves in one standard size.

The most common materials used for tracing service lines are copper, stainless steel, and

carbon steel. Copper tube is the most popular because of its heat transfer characteristics.

Copper type L, ASTM B-88, is used often for piping and ASTM B-75 for tubing. Stainless

steel tubing should be selected if there is the possibility of a corrosive environment. Carbon

steel, ASTM A-53, schedule 40, is often a client preference based on existing standard pipe

specifications, but is not generally recommended for tracer lines because of its tendency

to corrode easily and produce rust that flakes off inside the tracer pipe and produces stop-

pages. In addition, the carbon steel pipe is subject to corrosion, which will cause the pipe

to fail much more quickly than copper or stainless steel. Carbon steel is frequently used for

steam and condensate headers.

Fittings for copper and stainless steel are usually the compression type, similar to

Swagelok. Screwed or welded joints are used to install steel piping. Bends in copper pipe

are made with a tube bender, rather than fittings, with care taken not to crimp the tracer

pipe. Unions are commonly provided in tracer lines at flanges and other connections.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.