Page 300 - Failure Analysis Case Studies II

P. 300

285

CORROSION OF CENTRAL HEATING SYSTEMS

D. R. H. JONES

Department of Engineering, University of Cambridge, Trumpington Street, Cambridge CB2 IPZ, U.K.

(Received 20 March 1YY7)

Abstract-This paper begins by summarizing the main mechanisms by which components in central heating

systems can corrode, and indicating the factors which can increase or decrease the rates of corrosion. The

basic principles are then applied to the analysis of three case studies of corrosion failure in heating systems:

rusting through of mild steel radiators after only 2 years in service; premature pitting corrosion of aluminium

heat-exchanger tubes; and external corrosion of mild steel water pipes. Q 1997 Elsevier Science Ltd

Keywords: Bacterial corrosion, corrosion, corrosion protection, pitting corrosion, heat-exchanger failures

1. BACKGROUND

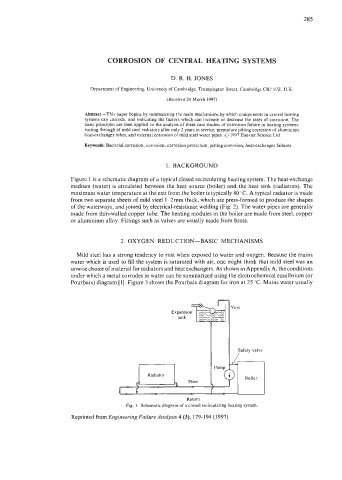

Figure 1 is a schematic diagram of a typical closed recirculating heating system. The heat-exchange

medium (water) is circulated between the heat source (boiler) and the heat sink (radiators). The

maximum water temperature at the exit from the boiler is typically 80 "C. A typical radiator is made

from two separate sheets of mild steel 1-2 mm thick, which are press-formed to produce the shapes

of the waterways, and joined by electrical-resistance welding (Fig. 2). The water pipes are generally

made from thin-walled copper tube. The heating modules in the boiler are made from steel, copper

or aluminium alloy. Fittings such as valves are usually made from brass.

2. OXYGEN REDUCTION-BASIC MECHANISMS

Mild steel has a strong tendency to rust when exposed to water and oxygen. Because the mains

water which is used to fill the system is saturated with air, one might think that mild steel was an

unwise choice ofmaterial for radiators and heat exchangers. As shown in Appendix A, the conditions

under which a metal corrodes in water can be summarized using the electrochemical equilbrium (or

Pourbaix) diagram [I]. Figure 3 shows the Pourbaix diagram for iron at 25 "C. Mains water usually

~ 171 """ rmq=

Radiator

~

Return

Fig. 1. Schematic diagram of a closed recirculating heating system.

Reprinted from Engineering Failure Analysis 4 (3), 179-1 94 (I 997)