Page 302 - Failure Analysis Case Studies II

P. 302

287

Pump

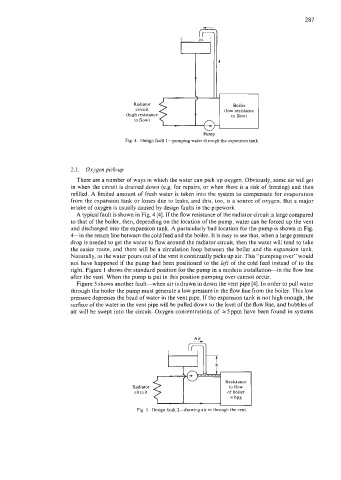

Fig. 4. Design fault 1-pumping water through the expansion tank.

2.1. Oxygen pick-up

There are a number of ways in which the water can pick up oxygen. Obviously, some air will get

in when the circuit is drained down (e.g. for repairs, or when there is a risk of freezing) and then

refilled. A limited amount of fresh water is taken into the system to compensate for evaporation

from thc cxpansion tank or losses due to leaks, and this, too, is a source of oxygen. But a major

intake of oxygen is usually caused by design faults in the pipework.

A typical fault is shown in Fig. 4 [4]. If the flow resistance of the radiator circuit is large compared

to that of the boiler, then, depending on the location of the pump, water can be forced up the vent

and discharged into the expansion tank. A particularly bad location for the pump is shown in Fig.

&in the return line between the cold feed and the boiler. It is easy to see that, when a large pressure

drop is needed to get the water to flow around the radiator circuit, then the water will tend to take

the easier route, and there will be a circulation loop between the boiler and the expansion tank.

Naturally, as the water pours out of the vent it continually picks up air. This “pumping over” would

not have happened if the pump had been positioned to the left of the cold feed instead of to the

right. Figure 1 shows the standard position for the pump in a modern installation-in the flow line

after the vent. When the pump is put in this position pumping over cannot occur.

Figure 5 shows another fault-when air is drawn in down the vent pipe [4]. In order to pull water

through the boiler the pump must generate a low pressure in the flow line from the boiler. This low

pressure depresses the head of water in the vent pipe. If the expansion tank is not high enough, the

surface of the water in the vent pipe will be pulled down to the level of the flow line, and bubbles of

air will be swept into the circuit. Oxygen concentrations of w 5 ppm have been found in systems

Air

Radiator

circuit

Fig. 5. Design fault 24rawing air in through the vent.