Page 179 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 179

160 Fluid Mechanics, Thermodynamics of Turbomachinery

High-pressure

air source

Adjustable

dashpot

Injection

plenum

Valve area detemined

by tip deflection of Reed Cantilevered

reed valve seal reed valve

Tip

Injection flow

Rotor

Air flow to compressor

Hub

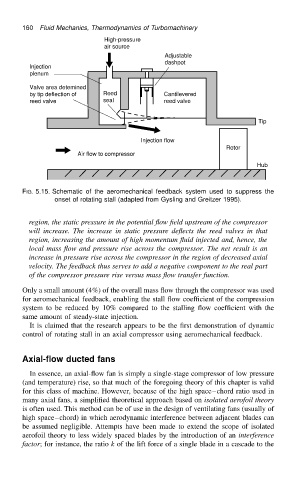

FIG. 5.15. Schematic of the aeromechanical feedback system used to suppress the

onset of rotating stall (adapted from Gysling and Greitzer 1995).

region, the static pressure in the potential flow field upstream of the compressor

will increase. The increase in static pressure deflects the reed valves in that

region, increasing the amount of high momentum fluid injected and, hence, the

local mass flow and pressure rise across the compressor. The net result is an

increase in pressure rise across the compressor in the region of decreased axial

velocity. The feedback thus serves to add a negative component to the real part

of the compressor pressure rise versus mass flow transfer function.

Only a small amount (4%) of the overall mass flow through the compressor was used

for aeromechanical feedback, enabling the stall flow coefficient of the compression

system to be reduced by 10% compared to the stalling flow coefficient with the

same amount of steady-state injection.

It is claimed that the research appears to be the first demonstration of dynamic

control of rotating stall in an axial compressor using aeromechanical feedback.

Axial-flow ducted fans

In essence, an axial-flow fan is simply a single-stage compressor of low pressure

(and temperature) rise, so that much of the foregoing theory of this chapter is valid

for this class of machine. However, because of the high space chord ratio used in

many axial fans, a simplified theoretical approach based on isolated aerofoil theory

is often used. This method can be of use in the design of ventilating fans (usually of

high space chord) in which aerodynamic interference between adjacent blades can

be assumed negligible. Attempts have been made to extend the scope of isolated

aerofoil theory to less widely spaced blades by the introduction of an interference

factor; for instance, the ratio k of the lift force of a single blade in a cascade to the