Page 202 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 202

Be st Practice 3 .19 Compressor Best Practices

Best

Best

Best Practice 3.19Practice 3.19Practice 3.19

Use tilt pad or multi-lobe type bearings and avoid lemon vibration issues that have resulted in long periods of

bore (elliptical) and offset sleeve types to ensure accept- downtime and large revenue losses in un-spared integral

able vibration characteristics at all speeds and loads in all geared compressor installations.

between bearing and integral geared compressors.

Lemon bore (elliptical) and offset sleeve type bearings do not pre- Benchmarks

vent vibration whirl and/or whip (excessive vibration at a critical speed This best practice has been used since the early 1980s, after experi-

frequency) if the attitude (bearing load) angle falls in the major axis of encing a situation where an offset sleeve bearing had to be replaced

the bearing. during test to meet the vibration specification prior to field operation.

The attitude angle varies with the transmitted power in all integral The prohibition of lemon bore and offset sleeve bearings since that

gear compressors. time has resulted in integral geared compressor reliabilities of greater

Many integral gear compressors still use this type of bearing. than 97% and centrifugal compressor reliabilities of greater than

99.7%.

Lessons Learned

The use of lemon bore or offset sleeve type bearings,

particularly in integral geared compressors, have caused

B.P. 3.19. Supporting Material Straight sleeve bearings are used for low shaft speeds (less

than 5,000 RPM) or for older turbo-compressor designs. Fre-

quently, they are modified to incorporate a pressure dam, in the

Hydrodynamic bearing types direction of rotation. The pressure dam must be positioned in

the top half of the bearing to increase the load vector. This

Regardless of the type of hydrodynamic bearing, all bearing action ensures that the tangential force vector will be small

surfaces are lined with a soft, surface material made from relative to the load vector, thus preventing shaft instability. It

a composition of tin and lead. This material is known as Babbitt. should be noted that incorrect assembly of the pressure dam in

Its melting temperature is above 200 C (400 F), but under load the lower half of the bearing will render this type of bearing

will begin to deform at approximately 160 C (320 F). Typical unstable. Other alternatives to prevent rotor instabilities are

thickness of Babbitt over steel is 1.5 mm (0.060). Bearing em- noted in Figure 3.19.2 for use when the shaft speed is high.

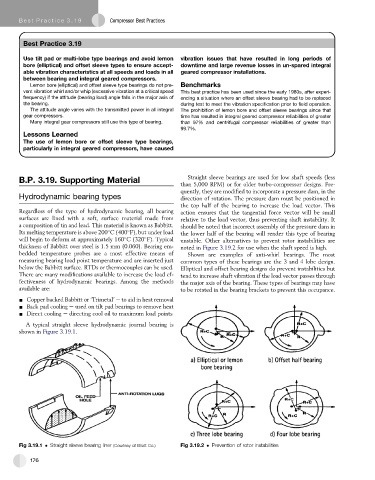

bedded temperature probes are a most effective means of Shown are examples of anti-whirl bearings. The most

measuring bearing load point temperature and are inserted just common types of these bearings are the 3 and 4 lobe design.

below the Babbitt surface. RTDs or thermocouples can be used. Elliptical and offset bearing designs do prevent instabilities but

There are many modifications available to increase the load ef- tend to increase shaft vibration if the load vector passes through

fectiveness of hydrodynamic bearings. Among the methods the major axis of the bearing. These types of bearings may have

available are: to be rotated in the bearing brackets to prevent this occupance.

- Copper backed Babbitt or ‘Trimetal’ e to aid in heat removal

- Back pad cooling e used on tilt pad bearings to remove heat

- Direct cooling e directing cool oil to maximum load points

A typical straight sleeve hydrodynamic journal bearing is

shown in Figure 3.19.1.

Fig 3.19.1 Straight sleeve bearing liner (Courtesy of Elliott Co.) Fig 3.19.2 Prevention of rotor instabilities

176