Page 205 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 205

Compressor Best Practices Best Practice 3 .19

Vibration is the result of a system being acted on by an

excitation.

This excitation produces a dynamic force by the relationship:

F DYNAMIC =Ma

Where: M = Mass (Weight/g)

2

g = Acceleration due to gravity (386 IN/SEC )

2

a = Acceleration of mass M (IN/SEC )

Vibration can be:

Lateral _________ ↕ __________

Axial → _________________ ←

Torsional _____________________

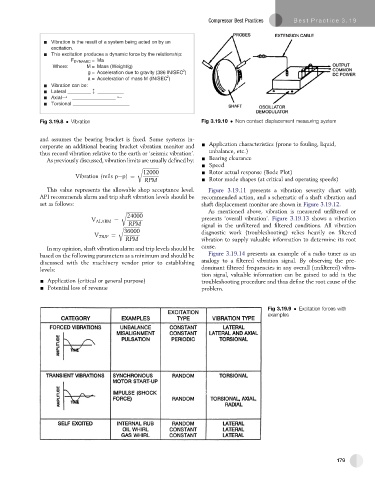

Fig 3.19.8 Vibration Fig 3.19.10 Non contact displacement measuring system

and assumes the bearing bracket is fixed. Some systems in-

corporate an additional bearing bracket vibration monitor and - Application characteristics (prone to fouling, liquid,

thus record vibration relative to the earth or ‘seismic vibration’. unbalance, etc.)

As previously discussed, vibration limits are usually defined by: - Bearing clearance

- Speed

r ffiffiffiffiffiffiffiffiffiffiffiffiffiffi

12000 - Rotor actual response (Bode Plot)

Vibration ðmils pepÞ¼

RPM - Rotor mode shapes (at critical and operating speeds)

This value represents the allowable shop acceptance level. Figure 3.19.11 presents a vibration severity chart with

API recommends alarm and trip shaft vibration levels should be recommended action, and a schematic of a shaft vibration and

set as follows: shaft displacement monitor are shown in Figure 3.19.12.

As mentioned above, vibration is measured unfiltered or

r ffiffiffiffiffiffiffiffiffiffiffiffiffiffi

24000

V ALARM ¼ presents ‘overall vibration’. Figure 3.19.13 shows a vibration

RPM

r ffiffiffiffiffiffiffiffiffiffiffiffiffiffi signal in the unfiltered and filtered conditions. All vibration

36000 diagnostic work (troubleshooting) relies heavily on filtered

V TRIP ¼

RPM vibration to supply valuable information to determine its root

In my opinion, shaft vibration alarm and trip levels should be cause.

based on the following parameters as a minimum and should be Figure 3.19.14 presents an example of a radio tuner as an

discussed with the machinery vendor prior to establishing analogy to a filtered vibration signal. By observing the pre-

levels: dominant filtered frequencies in any overall (unfiltered) vibra-

tion signal, valuable information can be gained to add in the

- Application (critical or general purpose) troubleshooting procedure and thus define the root cause of the

- Potential loss of revenue problem.

Fig 3.19.9 Excitation forces with

examples

179