Page 214 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 214

Be st Practice 3 .22 Compressor Best Practices

Best Practice 3.22

Oil seals should be designed or modified to incorporate Lessons Learned

a flow through port if the difference between operating Compressor applications using oil seals in high suction

seal reference pressure and start-up pressure is greater pressure applications frequently have low seal MTBFs.

than 1,375 kPa (200 psi). RCFA investigations show that low pressure start-up con-

All compressor oil seals incorporate an atmospheric bushing. The ditions (nitrogen purge operation, etc.) with seals not using

atmospheric bushing flow is directly proportional to the seal reference a flow through design is the root cause of low MTBFs.

gas pressure since the seal system provides sealing oil at some con-

stant differential pressure above the reference pressure. Benchmarks

In many seal designs, the atmospheric bushing clearance provides

This best practice has been used since 1990, during the design phase

the only means of seal cooling and is designed to provide sufficient

to require flow-through type seal designs for high suction pressure

cooling oil flow for the rated operating reference gas pressure.

compressor applications where there is a difference of more than 1,375

If the reference pressure at start-up is less than 1,375 kPa (200 psid)

kPa (200 psi) between start-up and operating reference pressures.

than the operating reference pressure, insufficient atmospheric bush- Seal designs can be modified in the field to incorporate flow-

ing flow will be present during start-up, and bushing wear can result through designs, but require redesign of the seal oil system and seal

and cause a compressor trip on low differential seal oil pressure. housing modifications in the field.

Incorporating a flow through port into the seal design will allow

Use of flow through oil seals has resulted in seal MTBFs in excess of

sufficient cooling oil flow during low reference gas conditions that will 100 months, and compressor reliabilities in excess of 99.7%.

occur during start-up.

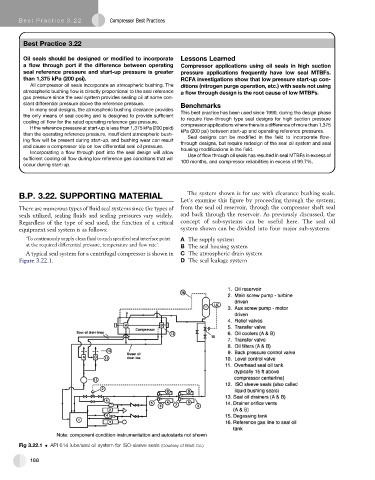

B.P. 3.22. SUPPORTING MATERIAL The system shown is for use with clearance bushing seals.

Let’sexamine this figure by proceeding through the system;

There are numerous types of fluid seal systems since the types of from the seal oil reservoir, through the compressor shaft seal

seals utilized, sealing fluids and sealing pressures vary widely. and back through the reservoir. As previously discussed, the

Regardless of the type of seal used, the function of a critical concept of sub-systems can be useful here. The seal oil

equipment seal system is as follows: system shown can be divided into four major sub-systems:

‘To continuously supply clean fluid to each specified seal interface point A The supply system

at the required differential pressure, temperature and flow rate’. B The seal housing system

A typical seal system for a centrifugal compressor is shown in C The atmospheric drain system

Figure 3.22.1. D The seal leakage system

Fig 3.22.1 API 614 lube/seal oil system for ISO-sleeve seals (Courtesy of Elliott Co.)

188