Page 226 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 226

Be st Practice 3 .23 Compressor Best Practices

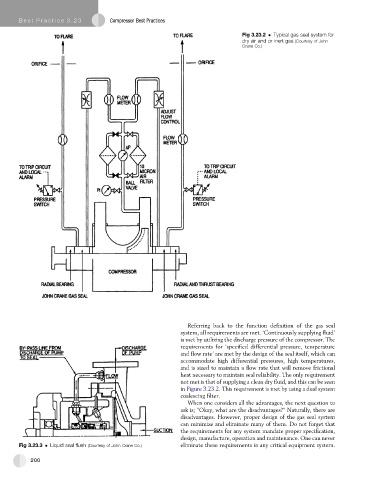

Fig 3.23.2 Typical gas seal system for

dry air and or inert gas (Courtesy of John

Crane Co.)

Referring back to the function definition of the gas seal

system, all requirements are met. ‘Continuously supplying fluid’

is met by utilizing the discharge pressure of the compressor. The

requirements for ‘specified differential pressure, temperature

and flow rate’ are met by the design of the seal itself, which can

accommodate high differential pressures, high temperatures,

and is sized to maintain a flow rate that will remove frictional

heat necessary to maintain seal reliability. The only requirement

not met is that of supplying a clean dry fluid, and this can be seen

in Figure 3.23.2. This requirement is met by using a dual system

coalescing filter.

When one considers all the advantages, the next question to

ask is; “Okay, what are the disadvantages?” Naturally, there are

disadvantages. However, proper design of the gas seal system

can minimize and eliminate many of them. Do not forget that

the requirements for any system mandate proper specification,

design, manufacture, operation and maintenance. One can never

Fig 3.23.3 Liquid seal flush (Courtesy of John Crane Co.) eliminate these requirements in any critical equipment system.

200