Page 506 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 506

Pump Mechanical Seal Flush Best Practices Be st Practice 8.6

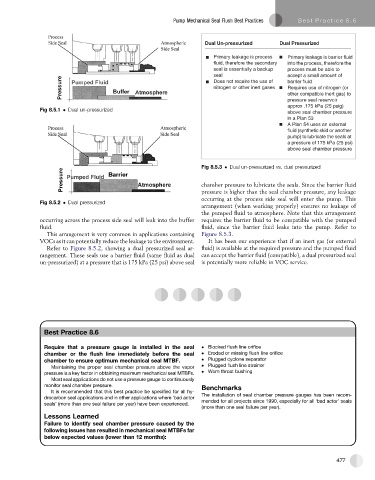

Dual Un-pressurized Dual Pressurized

Primary leakage is process Primary leakage is barrier fluid

fluid, therefore the secondary into the process, therefore the

seal is essentially a backup process must be able to

seal accept a small amount of

Does not require the use of barrier fluid

nitrogen or other inert gases Requires use of nitrogen (or

other compatible inert gas) to

pressure seal reservoir

approx .175 kPa (25 psig)

Fig 8.5.1 Dual un-pressurized

above seal chamber pressure

in a Plan 53

A Plan 54 uses an external

fluid (synthetic skid or another

pump) to lubricate the seals at

a pressure of 175 kPa (25 psi)

above seal chamber pressure

Fig 8.5.3 Dual un-pressurized vs. dual pressurized

chamber pressure to lubricate the seals. Since the barrier fluid

pressure is higher than the seal chamber pressure, any leakage

occurring at the process side seal will enter the pump. This

Fig 8.5.2 Dual pressurized

arrangement (when working properly) ensures no leakage of

the pumped fluid to atmosphere. Note that this arrangement

occurring across the process side seal will leak into the buffer requires the barrier fluid to be compatible with the pumped

fluid. fluid, since the barrier fluid leaks into the pump. Refer to

This arrangement is very common in applications containing Figure 8.5.3.

VOCs as it can potentially reduce the leakage to the environment. It has been our experience that if an inert gas (or external

Refer to Figure 8.5.2, showing a dual pressurized seal ar- fluid) is available at the required pressure and the pumped fluid

rangement. These seals use a barrier fluid (same fluid as dual can accept the barrier fluid (compatible), a dual pressurized seal

un-pressurized) at a pressure that is 175 kPa (25 psi) above seal is potentially more reliable in VOC service.

Best Practice 8.6Practice 8.6

Best

Require that a pressure gauge is installed in the seal Blocked flush line orifice

chamber or the flush line immediately before the seal Eroded or missing flush line orifice

chamber to ensure optimum mechanical seal MTBF. Plugged cyclone separator

Maintaining the proper seal chamber pressure above the vapor Plugged flush line strainer

pressure is a key factor in obtaining maximum mechanical seal MTBFs. Worn throat bushing

Most seal applications do not use a pressure gauge to continuously

monitor seal chamber pressure. Benchmarks

It is recommended that this best practice be specified for all hy-

The installation of seal chamber pressure gauges has been recom-

drocarbon seal applications and in other applications where ‘bad actor

mended for all projects since 1990, especially for all ‘bad actor’ seals

seals’ (more than one seal failure per year) have been experienced.

(more than one seal failure per year).

Lessons Learned

Failure to identify seal chamber pressure caused by the

following issues has resulted in mechanical seal MTBFs far

below expected values (lower than 12 months):

477