Page 351 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 351

1656_C007.fm Page 331 Monday, May 23, 2005 5:54 PM

Fracture Toughness Testing of Metals 331

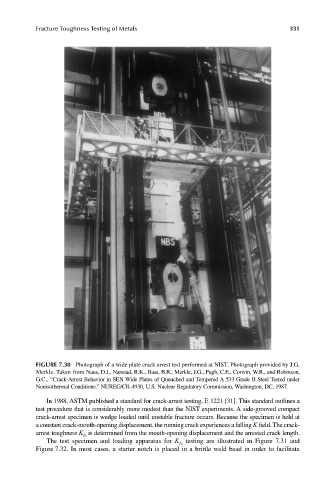

FIGURE 7.30 Photograph of a wide plate crack arrest test performed at NIST. Photograph provided by J.G.

Merkle. Taken from Naus, D.J., Nanstad, R.K., Bass, B.R., Merkle, J.G., Pugh, C.E., Corwin, W.R., and Robinson,

G.C., ‘‘Crack-Arrest Behavior in SEN Wide Plates of Quenched and Tempered A 533 Grade B Steel Tested under

Nonisothermal Conditions.’’ NUREG/CR-4930, U.S. Nuclear Regulatory Commission, Washington, DC, 1987.

In 1988, ASTM published a standard for crack-arrest testing, E 1221 [31]. This standard outlines a

test procedure that is considerably more modest than the NIST experiments. A side-grooved compact

crack-arrest specimen is wedge loaded until unstable fracture occurs. Because the specimen is held at

a constant crack-mouth-opening displacement, the running crack experiences a falling K field. The crack-

arrest toughness K is determined from the mouth-opening displacement and the arrested crack length.

Ia

The test specimen and loading apparatus for K testing are illustrated in Figure 7.31 and

Ia

Figure 7.32. In most cases, a starter notch is placed in a brittle weld bead in order to facilitate