Page 393 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 393

1656_C008.fm Page 373 Monday, May 23, 2005 5:59 PM

Fracture Testing of Nonmetals 373

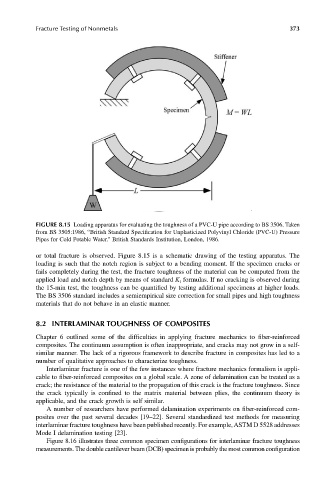

FIGURE 8.15 Loading apparatus for evaluating the toughness of a PVC-U pipe according to BS 3506. Taken

from BS 3505:1986, “British Standard Specification for Unplasticized Polyvinyl Chloride (PVC-U) Pressure

Pipes for Cold Potable Water.” British Standards Institution, London, 1986.

or total fracture is observed. Figure 8.15 is a schematic drawing of the testing apparatus. The

loading is such that the notch region is subject to a bending moment. If the specimen cracks or

fails completely during the test, the fracture toughness of the material can be computed from the

applied load and notch depth by means of standard K formulas. If no cracking is observed during

I

the 15-min test, the toughness can be quantified by testing additional specimens at higher loads.

The BS 3506 standard includes a semiempirical size correction for small pipes and high toughness

materials that do not behave in an elastic manner.

8.2 INTERLAMINAR TOUGHNESS OF COMPOSITES

Chapter 6 outlined some of the difficulties in applying fracture mechanics to fiber-reinforced

composites. The continuum assumption is often inappropriate, and cracks may not grow in a self-

similar manner. The lack of a rigorous framework to describe fracture in composites has led to a

number of qualitative approaches to characterize toughness.

Interlaminar fracture is one of the few instances where fracture mechanics formalism is appli-

cable to fiber-reinforced composites on a global scale. A zone of delamination can be treated as a

crack; the resistance of the material to the propagation of this crack is the fracture toughness. Since

the crack typically is confined to the matrix material between plies, the continuum theory is

applicable, and the crack growth is self similar.

A number of researchers have performed delamination experiments on fiber-reinforced com-

posites over the past several decades [19–22]. Several standardized test methods for measuring

interlaminar fracture toughness have been published recently. For example, ASTM D 5528 addresses

Mode I delamination testing [23].

Figure 8.16 illustrates three common specimen configurations for interlaminar fracture toughness

measurements. The double cantilever beam (DCB) specimen is probably the most common configuration