Page 394 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 394

1656_C008.fm Page 374 Monday, May 23, 2005 5:59 PM

374 Fracture Mechanics: Fundamentals and Applications

(a)

(b)

(c)

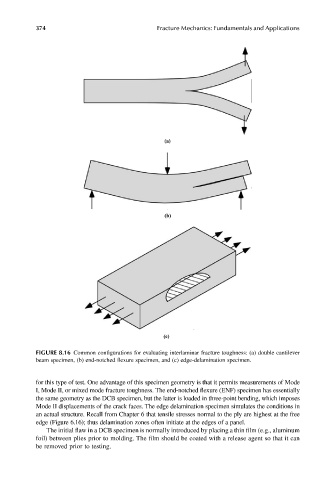

FIGURE 8.16 Common configurations for evaluating interlaminar fracture toughness: (a) double cantilever

beam specimen, (b) end-notched flexure specimen, and (c) edge-delamination specimen.

for this type of test. One advantage of this specimen geometry is that it permits measurements of Mode

I, Mode II, or mixed mode fracture toughness. The end-notched flexure (ENF) specimen has essentially

the same geometry as the DCB specimen, but the latter is loaded in three-point bending, which imposes

Mode II displacements of the crack faces. The edge delamination specimen simulates the conditions in

an actual structure. Recall from Chapter 6 that tensile stresses normal to the ply are highest at the free

edge (Figure 6.16); thus delamination zones often initiate at the edges of a panel.

The initial flaw in a DCB specimen is normally introduced by placing a thin film (e.g., aluminum

foil) between plies prior to molding. The film should be coated with a release agent so that it can

be removed prior to testing.