Page 285 - Fundamentals of Reservoir Engineering

P. 285

OILWELL TESTING 222

CLOCK

VERTICAL CHART

MOVEMENT ∝ TIME

STATIC PRESSURE-

DEPTH SURVEY

CHART FLOWING PRESSURE-

PRESSURE DEPTH SURVEY

(a) p ws

p wf

STYLUS

t ∆

TIME BASE LINE

STYLUS MOVEMENT (b)

∝ PRESSURE

BOURDON PRESSURE ELEMENT

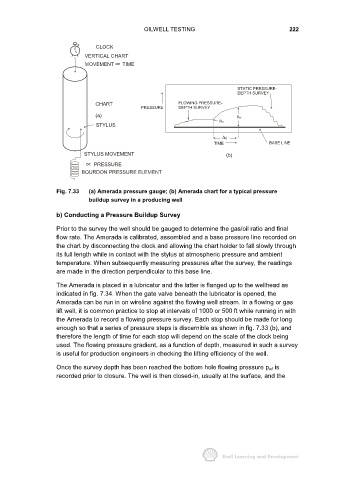

Fig. 7.33 (a) Amerada pressure gauge; (b) Amerada chart for a typical pressure

buildup survey in a producing well

b) Conducting a Pressure Buildup Survey

Prior to the survey the well should be gauged to determine the gas/oil ratio and final

flow rate. The Amerada is calibrated, assembled and a base pressure line recorded on

the chart by disconnecting the clock and allowing the chart holder to fall slowly through

its full length while in contact with the stylus at atmospheric pressure and ambient

temperature. When subsequently measuring pressures after the survey, the readings

are made in the direction perpendicular to this base line.

The Amerada is placed in a lubricator and the latter is flanged up to the wellhead as

indicated in fig. 7.34. When the gate valve beneath the lubricator is opened, the

Amerada can be run in on wireline against the flowing well stream. In a flowing or gas

lift well, it is common practice to stop at intervals of 1000 or 500 ft while running in with

the Amerada to record a flowing pressure survey. Each stop should be made for long

enough so that a series of pressure steps is discernible as shown in fig. 7.33 (b), and

therefore the length of time for each stop will depend on the scale of the clock being

used. The flowing pressure gradient, as a function of depth, measured in such a survey

is useful for production engineers in checking the lifting efficiency of the well.

Once the survey depth has been reached the bottom hole flowing pressure p wf is

recorded prior to closure. The well is then closed-in, usually at the surface, and the