Page 286 - Fundamentals of Reservoir Engineering

P. 286

OILWELL TESTING 223

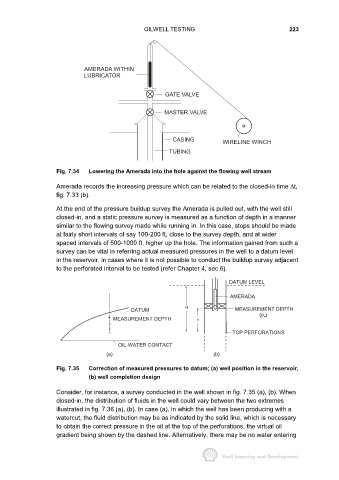

AMERADA WITHIN

LUBRICATOR

GATE VALVE

MASTER VALVE

CASING WIRELINE WINCH

TUBING

Fig. 7.34 Lowering the Amerada into the hole against the flowing well stream

Amerada records the increasing pressure which can be related to the closed-in time ∆t,

fig. 7.33 (b).

At the end of the pressure buildup survey the Amerada is pulled out, with the well still

closed-in, and a static pressure survey is measured as a function of depth in a manner

similar to the flowing survey made while running in. In this case, stops should be made

at fairly short intervals of say 100-200 ft, close to the survey depth, and at wider

spaced intervals of 500-1000 ft, higher up the hole. The information gained from such a

survey can be vital in referring actual measured pressures in the well to a datum level

in the reservoir, in cases where it is not possible to conduct the buildup survey adjacent

to the perforated interval to be tested (refer Chapter 4, sec.6).

DATUM LEVEL

AMERADA

H

DATUM MEASUREMENT DEPTH

(p )

m

MEASUREMENT DEPTH h

TOP PERFORATIONS

OIL-WATER CONTACT

(a) (b)

Fig. 7.35 Correction of measured pressures to datum; (a) well position in the reservoir,

(b) well completion design

Consider, for instance, a survey conducted in the well shown in fig. 7.35 (a), (b). When

closed-in, the distribution of fluids in the well could vary between the two extremes

illustrated in fig. 7.36 (a), (b). In case (a), in which the well has been producing with a

watercut, the fluid distribution may be as indicated by the solid line, which is necessary

to obtain the correct pressure in the oil at the top of the perforations, the virtual oil

gradient being shown by the dashed line. Alternatively, there may be no water entering