Page 399 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 399

354 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

Legend

X Valve on/off

Backwash X Valve-reg.

water

storage P Pump

Headwater Flow meter

Influent

Washwater trough X Water surface

Surface wash X P

Gullet

Waste Treated

Filter media X X P water

P Air

Air wash X storage

Gravel support X

X

Under-drain lateral Filtered water

Air lateral

X

Filter-to-waste

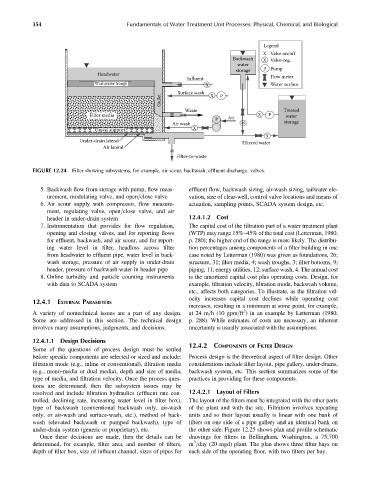

FIGURE 12.24 Filter showing subsystems, for example, air scour, backwash, effluent discharge, valves.

5. Backwash flow from storage with pump, flow meas- effluent flow, backwash sizing, air-wash sizing, tailwater ele-

urement, modulating valve, and open=close valve vation, size of clear-well, control valve locations and means of

6. Air scour supply with compressor, flow measure- actuation, sampling points, SCADA system design, etc.

ment, regulating valve, open=close valve, and air

header in under-drain system 12.4.1.2 Cost

7. Instrumentation that provides for flow regulation, The capital cost of the filtration part of a water treatment plant

opening and closing valves, and for reporting flows (WTP) may range 15%–45% of the total cost (Letterman, 1980,

for effluent, backwash, and air scour, and for report- p. 280); the higher end of the range is more likely. The distribu-

ing water level in filter, headloss across filter tion percentages among components of a filter building in one

from headwater to effluent pipe, water level in back- case noted by Letterman (1980) was given as foundations, 26;

wash storage, pressure of air supply in under-drain structure, 31; filter media, 4; wash troughs, 3; filter bottoms, 9;

header, pressure of backwash water in header pipe piping, 11; energy utilities, 12; surface wash, 4. The annual cost

8. Online turbidity and particle counting instruments is the amortized capital cost plus operating costs. Design, for

with data to SCADA system example, filtration velocity, filtration mode, backwash volume,

etc., affects both categories. To illustrate, as the filtration vel-

ocity increases capital cost declines while operating cost

12.4.1 EXTERNAL PARAMETERS

increases, resulting in a minimum at some point, for example,

2

A variety of nontechnical issues are a part of any design. at 24 m=h (10 gpm=ft ) in an example by Letterman (1980,

Some are addressed in this section. The technical design p. 288). While estimates of costs are necessary, an inherent

involves many assumptions, judgments, and decisions. uncertainty is usually associated with the assumptions.

12.4.1.1 Design Decisions

12.4.2 COMPONENTS OF FILTER DESIGN

Some of the questions of process design must be settled

before specific components are selected or sized and include: Process design is the theoretical aspect of filter design. Other

filtration mode (e.g., inline or conventional), filtration media considerations include filter layout, pipe gallery, under-drains,

(e.g., mono-media or dual media), depth and size of media, backwash system, etc. This section summarizes some of the

type of media, and filtration velocity. Once the process ques- practices in providing for these components.

tions are determined, then the subsystem issues may be

resolved and include filtration hydraulics (effluent rate con- 12.4.2.1 Layout of Filters

trolled, declining rate, increasing water level in filter box), The layout of the filters must be integrated with the other parts

type of backwash (conventional backwash only, air-wash of the plant and with the site. Filtration involves repeating

only, or air-wash and surface-wash, etc.), method of back- units and so their layout usually is linear with one bank of

wash (elevated backwash or pumped backwash), type of filters on one side of a pipe gallery and an identical bank on

under-drain system (generic or proprietary), etc. the other side. Figure 12.25 shows plan and profile schematic

Once these decisions are made, then the details can be drawings for filters in Bellingham, Washington, a 75,700

3

determined, for example, filter area, and number of filters, m =day (20 mgd) plant. The plan shows three filter bays on

depth of filter box, size of influent channel, sizes of pipes for each side of the operating floor, with two filters per bay.