Page 405 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 405

360 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

Looking at the filter box in more detail, its depth depends on Example 12.5 Depth of Filter Box

the under-drain system (e.g., size of under-drain plenum

or support media), media depth, and headloss desired. Problem statement

Headloss varies in the range, 2–3m (6–9 ft), but there is A filtration process will utilize a media depth of 3000 mm

no limit theoretically (except that turbidity breakthrough will (118 in.) of anthracite with d 10 ¼ 2 mm, UC ¼ 1.5. Assume

the backwash system is generic with laterals and gravel

occur eventually). Plenum systems can range 610–915 mm

support. An air wash system is also installed, but requires

(24–36 in.) in depth (Monk, 1987). If self backwashing

no additional depth. Assume that the tailwater weir is at

is used, a deeper filter box is required, as described by

the same elevation as the top of the media and that the

Monk (1987).

headloss permitted is 3048 mm (10 ft) and that the free-

board is 610 mm (24 in.).

Required

Example 12.4 Under-Drain Design

Estimate the depth of the filter box.

Problem statement Solution

2

2

A filter bed area of 120 m (1300 ft ) is proposed and a The depth of filter box is

generic under-drain system is to be used, that is, header

and laterals with orifices. The filtration rate proposed is D(filter box) ¼ D(gravel support) þ D(media)

2

HLR 22.0 m=h (9 gpm=ft ) and the backwash rate deter- þ headloss þ freeboard

2

mined by pilot tests is 61 m=h (25 gpm=ft ).

¼ 381 mm þ 3000 mm þ 3048 mm þ 610 mm

Required

Estimate the difference in orifice flow between the two (¼15 in: þ 118 in: þ 120 in: þ 24 in:)

extremes of the under-drain system, that is, at the first ¼ 7039 mm (23 ft 1in:)

orifice of the first lateral and the last orifice of the last

lateral.

12.4.4 BACKWASH

Solution

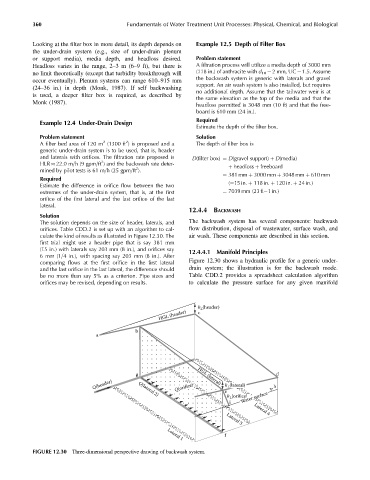

The solution depends on the size of header, laterals, and The backwash system has several components: backwash

orifices. Table CDD.2 is set up with an algorithm to cal- flow distribution, disposal of wastewater, surface wash, and

culate the kind of results as illustrated in Figure 12.30. The air wash. These components are described in this section.

first trial might use a header pipe that is say 381 mm

(15 in.) with laterals say 203 mm (8 in.), and orifices say

12.4.4.1 Manifold Principles

6mm(1=4 in.), with spacing say 203 mm (8 in.). After

Figure 12.30 shows a hydraulic profile for a generic under-

comparing flows at the first orifice in the first lateral

and the last orifice in the last lateral, the difference should drain system; the illustration is for the backwash mode.

be no more than say 5% as a criterion. Pipe sizes and Table CDD.2 provides a spreadsheet calculation algorithm

orifices may be revised, depending on results. to calculate the pressure surface for any given manifold

h (header)

L

HGL (header) c

b

a

g HGL (lateral) d

Q(header) Q(lateral 2) Q(orifice) h (lateral) h

L

e

Water surface

h L (orifice)

i Lateral 4

f Lateral 3

Lateral 1

FIGURE 12.30 Three-dimensional perspective drawing of backwash system.