Page 154 - Gas Purification 5E

P. 154

142 Gas PiiriJcation

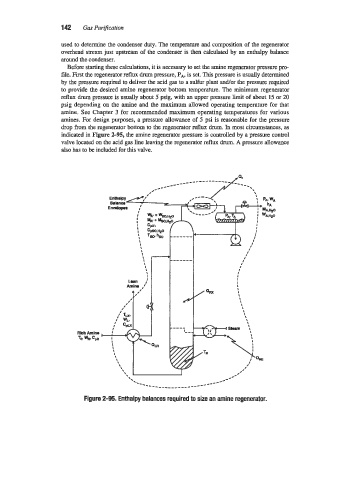

used to determine the condenser duty. The temperature and composition of the regenerator

overhead stream just upstream of the condenser is then calculated by an enthalpy balance

around the condenser.

Before starting these calculations, it is necessary to set the amine regenerator pressure pro-

file. First the regenerator reflux drum pressure, PA, is set. This pressure is usually determined

by the pressure required to deliver the acid gas to a sulfur plant andor the pressure required

to provide the desired amine regenerator bottom temperature. The minimum regenerator

reflux drum pressure is usually about 5 psig, with an upper pressure limit of about 15 or 20

psig depending on the amine and the maximum allowed operating temperature for that

amine. See Chapter 3 for recommended maximum operating temperatures for various

amines. For design purposes, a pressure allowance of 5 psi is reasonable for the pressure

drop from the regenerator bottom to the regenerator reflux drum. In most circumstances, as

indicated in Figure 2-95, the amine regenerator pressure is controlled by a pressure control

valve located on the acid gas line leaving the regenerator reflux drum. A pressure allowance

also has to be included for this \7alve.

I

Rkh Amino

TR. wR, ‘pR

,

,

c

__________--------

Figure 2-95. Enthalpy balances required to size an amine regenerator.