Page 123 - Gas Wettability of Reservoir Rock Surfaces with Porous Media

P. 123

Gas-wetting Alteration Agent and Gas-wetting CHAPTER 3 107

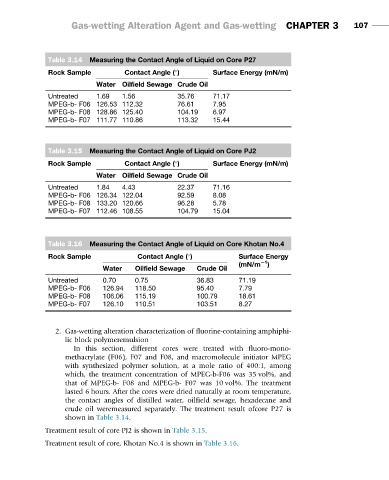

Table 3.14 Measuring the Contact Angle of Liquid on Core P27

Rock Sample Contact Angle ( ) Surface Energy (mN/m)

Water Oilfield Sewage Crude Oil

Untreated 1.69 1.56 35.76 71.17

MPEG-b- F06 126.53 112.32 76.61 7.95

MPEG-b- F08 128.86 125.40 104.19 6.97

MPEG-b- F07 111.77 110.86 113.32 15.44

Table 3.15 Measuring the Contact Angle of Liquid on Core PJ2

Rock Sample Contact Angle ( ) Surface Energy (mN/m)

Water Oilfield Sewage Crude Oil

Untreated 1.84 4.43 22.37 71.16

MPEG-b- F06 126.34 122.04 92.59 8.08

MPEG-b- F08 133.20 120.66 96.28 5.78

MPEG-b- F07 112.46 108.55 104.79 15.04

Table 3.16 Measuring the Contact Angle of Liquid on Core Khotan No.4

Rock Sample Contact Angle ( ) Surface Energy

(mN/m 21 )

Water Oilfield Sewage Crude Oil

Untreated 0.70 0.75 36.83 71.19

MPEG-b- F06 126.94 118.50 95.40 7.79

MPEG-b- F08 106.06 115.19 100.79 18.61

MPEG-b- F07 126.10 110.51 103.51 8.27

2. Gas-wetting alteration characterization of fluorine-containing amphiphi-

lic block polymeremulsion

In this section, different cores were treated with fluoro-mono-

methacrylate (F06), F07 and F08, and macromolecule initiator MPEG

with synthesized polymer solution, at a mole ratio of 400:1, among

which, the treatment concentration of MPEG-b-F06 was 35 vol%, and

that of MPEG-b- F08 and MPEG-b- F07 was 10 vol%. The treatment

lasted 6 hours. After the cores were dried naturally at room temperature,

the contact angles of distilled water, oilfield sewage, hexadecane and

crude oil weremeasured separately. The treatment result ofcore P27 is

shown in Table 3.14.

Treatment result of core PJ2 is shown in Table 3.15.

Treatment result of core, Khotan No.4 is shown in Table 3.16.