Page 197 - Geochemical Remote Sensing of The Sub-Surface

P. 197

174 V.T. Jones, M.D. Matthews and D.M. Richers

'-- ?.5cm L,

LICONE RUBBER SEAL

5cm OUTSIDE DIA.

5cm INSIDE DIA.

6. f INJECTION PORT

/-- THREADED P I PE I crn D ~ A.

/ ~ SEPTUM CAP FROM VARI AN

/ J S I L I CONE RUBBER

/ ~ /SEPTUM, ,crn DIA.

I~ r "i'-i~,NJECT,ON PO~T

llllilllllilllll i, - -

2cm ~ -' '-- -

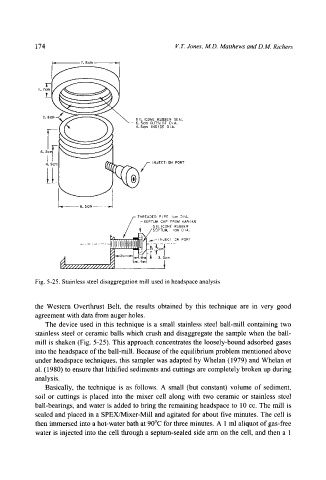

Fig. 5-25. Stainless steel disaggregation mill used in headspace analysis

the Western Overthrust Belt, the results obtained by this technique are in very good

agreement with data from auger holes.

The device used in this technique is a small stainless steel ball-mill containing two

stainless steel or ceramic balls which crush and disaggregate the sample when the ball-

mill is shaken (Fig. 5-25). This approach concentrates the loosely-bound adsorbed gases

into the headspace of the ball-mill. Because of the equilibrium problem mentioned above

under headspace techniques, this sampler was adapted by Whelan (1979) and Whelan et

al. (1980) to ensure that lithified sediments and cuttings are completely broken up during

analysis.

Basically, the technique is as follows. A small (but constant) volume of sediment,

soil or cuttings is placed into the mixer cell along with two ceramic or stainless steel

ball-bearings, and water is added to bring the remaining headspace to 10 cc. The mill is

sealed and placed in a SPEX/Mixer-Mill and agitated for about five minutes. The cell is

then immersed into a hot-water bath at 90~ for three minutes. A 1 ml aliquot of gas-free

water is injected into the cell through a septum-sealed side arm on the cell, and then a 1