Page 38 - Handbook of Adhesion Promoters

P. 38

2.9 Chemical bonding 31

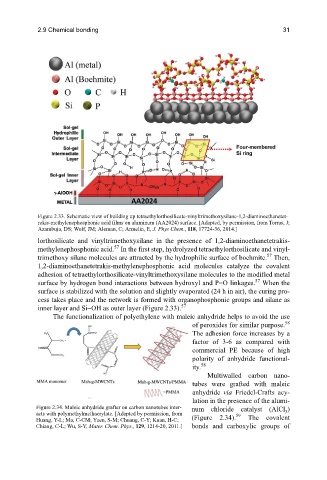

Figure 2.33. Schematic view of building up tetraethylorthosilicate-vinyltrimethoxysilane-1,2-diaminoethanetet-

rakis-methylenephosphonic acid films on aluminum (AA2024) surface. [Adapted, by permission, from Torras, J;

Azambuja, DS; Wolf, JM; Aleman, C; Armelin, E, J. Phys Chem., 118, 17724-36, 2014.]

lorthosilicate and vinyltrimethoxysilane in the presence of 1,2-diaminoethanetetrakis-

57

methylenephosphonic acid. In the first step, hydrolyzed tetraethylorthosilicate and vinyl-

57

trimethoxy silane molecules are attracted by the hydrophilic surface of boehmite. Then,

1,2-diaminoethanetetrakis-methylenephosphonic acid molecules catalyze the covalent

adhesion of tetraethylorthosilicate-vinyltrimethoxysilane molecules to the modified metal

57

surface by hydrogen bond interactions between hydroxyl and P=O linkages. When the

surface is stabilized with the solution and slightly evaporated (24 h in air), the curing pro-

cess takes place and the network is formed with organophosphonic groups and silane as

57

inner layer and Si−OH as outer layer (Figure 2.33).

The functionalization of polyethylene with maleic anhydride helps to avoid the use

of peroxides for similar purpose. 58

The adhesion force increases by a

factor of 3-6 as compared with

commercial PE because of high

polarity of anhydride functional-

58

ity.

Multiwalled carbon nano-

tubes were grafted with maleic

anhydride via Friedel-Crafts acy-

lation in the presence of the alumi-

Figure 2.34. Maleic anhydride grafter on carbon nanotubes inter- num chloride catalyst (AlCl )

3

acts with polymethylmethacrylate. [Adapted by permission, from (Figure 2.34). The covalent

59

Huang, Y-L; Ma, C-CM; Yuen, S-M; Chuang, C-Y; Kuan, H-C;

Chiang, C-L; Wu, S-Y, Mater. Chem. Phys., 129, 1214-20, 2011.] bonds and carboxylic groups of