Page 284 - Handbook of Civil Engineering Calculations, Second Edition

P. 284

PRESTRESSED CONCRETE 2.69

3. Determine whether the section moduli are excessive

Do this by setting f bf and f ti equal to their allowable values and computing the corresponding

values of f bi and f tf . Thus, f bf 0.85f bp 2334 425; therefore, f bp 2246 lb/sq.in.

( 15,486.2 kPa); f ti f tp 190 lb/sq.in. ( 1310.1 kPa); f bi f bp 2246 < 2400

lb/sq.in.( 16,548.0 kPa). This is acceptable. Also, f tf 0.85( 190) 1067 905 < 2250

lb/sq.in. ( 15,513.8 kPa); this is acceptable. The section moduli are therefore excessive.

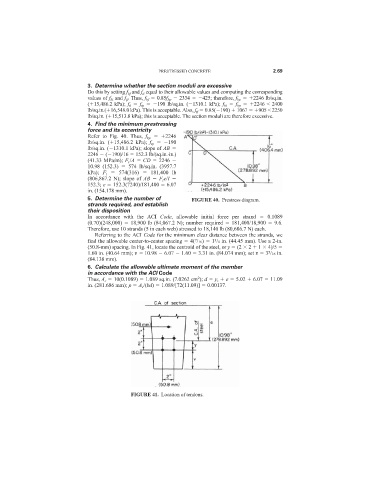

4. Find the minimum prestressing

force and its eccentricity

Refer to Fig. 40. Thus, f bp 2246

lb/sq.in. ( 15,486.2 kPa); f tp 190

lb/sq.in. ( 1310.1 kPa); slope of AB

2246 ( 190)/16 152.3 lb/(sq.in.·in.)

(41.33 MPa/m); F i /A CD 2246

10.98 (152.3) 574 lb/sq.in. (3957.7

kPa); F i 574(316) 181,400 lb

(806,867.2 N); slope of AB F i e/I

152.3; e 152.3(7240)/181,400 6.07

in. (154.178 mm).

5. Determine the number of FIGURE 40. Prestress diagram.

strands required, and establish

their disposition

In accordance with the ACI Code, allowable initial force per strand 0.1089

(0.70)(248,000) 18,900 lb (84,067.2 N); number required 181,400/18,900 9.6.

Therefore, use 10 strands (5 in each web) stressed to 18,140 lb (80,686.7 N) each.

Referring to the ACI Code for the minimum clear distance between the strands, we

3

7

find the allowable center-to-center spacing 4( /16) 1 /4 in. (44.45 mm). Use a 2-in.

(50.8-mm) spacing. In Fig. 41, locate the centroid of the steel, or y (2 2 1 4)/5

1.60 in. (40.64 mm); v 10.98 6.07 1.60 3.31 in. (84.074 mm); set v 3 /16 in.

5

(84.138 mm).

6. Calculate the allowable ultimate moment of the member

in accordance with the ACI Code

2

Thus, A s 10(0.1089) 1.089 sq.in. (7.0262 cm ); d y t e 5.02 6.07 11.09

in. (281.686 mm); p A s /(bd) 1.089/[72(11.09)] 0.00137.

FIGURE 41. Location of tendons.