Page 344 - Handbook of Materials Failure Analysis

P. 344

E:\SharedData\Quanta Data\Commercial\S\SGS\201\A-eds.spc

Label A: SGS A CCL22

Sn

Element Wt.% At.%

EDS SnL 91.43 90.89

SbL 7.65 7.42

CuK 0.91 1.7

Sb

Total 100 100

Cu

O S

C Pt

N Si

Cu

2.00 4.00 6.00 8.00 10.00 12.00 14.00 16.00 18.00 keV

(a) (b)

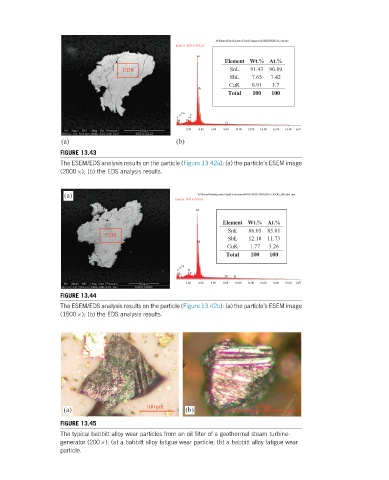

FIGURE 13.43

The ESEM/EDS analysis results on the particle (Figure 13.42a): (a) the particle’s ESEM image

(2000 ); (b) the EDS analysis results.

(a) E:\SharedData\Quanta Data\Commercial\S\SGS\2014\06\25\E-CRX85_001eds1.spc

Label A: SGS E CRX85

Sn

Element Wt.% At.%

SnL 86.05 85.01

EDS

SbL 12.18 11.73

Sb

CuK 1.77 3.26

Total 100 100

Cu

O

C Pt

Sn S

Cu Pt

2.00 4.00 6.00 8.00 10.00 12.00 14.00 16.00 18.00 keV

FIGURE 13.44

The ESEM/EDS analysis results on the particle (Figure 13.42b): (a) the particle’s ESEM image

(1500 ); (b) the EDS analysis results.

100µm 100µm

(a) (b)

FIGURE 13.45

The typical babbitt alloy wear particles from an oil filter of a geothermal steam turbine-

generator (200 ): (a) a babbitt alloy fatigue wear particle; (b) a babbitt alloy fatigue wear

particle.