Page 416 - Handbook of Materials Failure Analysis

P. 416

414 CHAPTER 16 Degradation of protective PVD coatings

Columnar grains

Transition structure

consisting of densely

packed fibrous grains

Porous structure

consisting of tapered Recrystallized

grain structure

crystallites separated

by voids

ZONE 3

ZONE 2

1.0

ZONE 1 0.9

ZONE T

0.8

0.7

30

0.6

0.5 Substrate

20

0.4

temperature (T/T M )

Argon 0.3

pressure 10 0.2

(m torr) 0.1

1

Influence of substrate temperature

and argon pressure on microstructure

of sputtered films

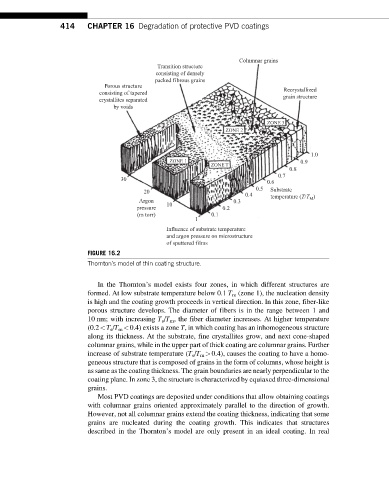

FIGURE 16.2

Thornton’s model of thin coating structure.

In the Thornton’s model exists four zones, in which different structures are

formed. At low substrate temperature below 0.1 T m (zone 1), the nucleation density

is high and the coating growth proceeds in vertical direction. In this zone, fiber-like

porous structure develops. The diameter of fibers is in the range between 1 and

10 nm; with increasing T s /T m , the fiber diameter increases. At higher temperature

(0.2<T s /T m <0.4) exists a zone T, in which coating has an inhomogeneous structure

along its thickness. At the substrate, fine crystallites grow, and next cone-shaped

columnar grains, while in the upper part of thick coating are columnar grains. Further

increase of substrate temperature (T s /T m >0.4), causes the coating to have a homo-

geneous structure that is composed of grains in the form of columns, whose height is

as same as the coating thickness. The grain boundaries are nearly perpendicular to the

coating plane. In zone 3, the structure is characterized by equiaxed three-dimensional

grains.

Most PVD coatings are deposited under conditions that allow obtaining coatings

with columnar grains oriented approximately parallel to the direction of growth.

However, not all columnar grains extend the coating thickness, indicating that some

grains are nucleated during the coating growth. This indicates that structures

described in the Thornton’s model are only present in an ideal coating. In real