Page 83 - Handbook of Materials Failure Analysis

P. 83

2 Case History 77

acceptable. In Refs. [30,31], it was argued that a deformation value of 1.5% can be

assumed as a good criterion for deciding the tubes substitution.

The method for failure forecast and prevention, based on LOTIS diameter mea-

surements, is reported here in order to show its reliability to determine the creep stage

of material after long-time service and decide whether tubes need to be replaced.

Therefore, metallurgical observations and creep tests were addressed to investigate

creep damage of tubes made of a HP-40 alloy and analyze the adopted criterion for

tubes decommissioning. In other words, it means verifying that diameter deforma-

tions lower than 1.5% are reasonably acceptable to ensure safe work until the next

plant stop, that is usually planned every 2 years.

2 CASE HISTORY

The reformer furnace considered in this chapter is located in Sicily near the

Tyrrhenian Sea (working today). The inspections reported in the following were car-

ried out in 2010 on radiant tubes that had been in service for more than 10 years.

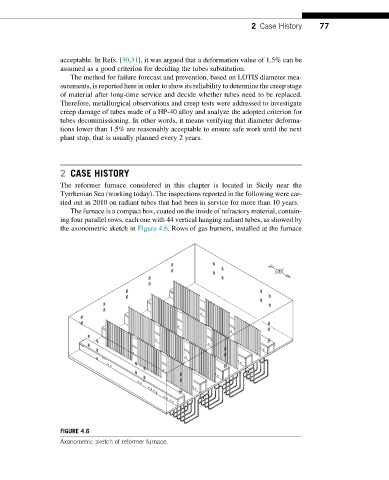

The furnace is a compact box, coated on the inside of refractory material, contain-

ing four parallel rows, each one with 44 vertical hanging radiant tubes, as showed by

the axonometric sketch in Figure 4.6. Rows of gas burners, installed at the furnace

FIGURE 4.6

Axonometric sketch of reformer furnace.