Page 64 - High Power Laser Handbook

P. 64

36 G a s , C h e m i c a l , a n d F r e e - E l e c t r o n L a s e r s Excimer Lasers 37

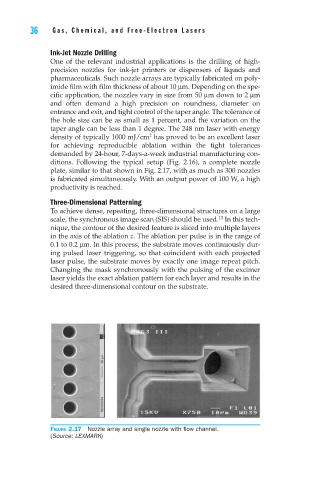

Ink-Jet Nozzle Drilling

One of the relevant industrial applications is the drilling of high-

precision nozzles for ink-jet printers or dispensers of liquids and

pharmaceuticals. Such nozzle arrays are typically fabricated on poly-

imide film with film thickness of about 10 mm. Depending on the spe-

cific application, the nozzles vary in size from 50 mm down to 2 mm

and often demand a high precision on roundness, diameter on

entrance and exit, and tight control of the taper angle. The tolerance of

the hole size can be as small as 1 percent, and the variation on the

taper angle can be less than 1 degree. The 248 nm laser with energy

2

density of typically 1000 mJ/cm has proved to be an excellent laser

for achieving reproducible ablation within the tight tolerances

demanded by 24-hour, 7-days-a-week industrial manufacturing con-

ditions. Following the typical setup (Fig. 2.16), a complete nozzle

plate, similar to that shown in Fig. 2.17, with as much as 300 nozzles

is fabricated simultaneously. With an output power of 100 W, a high

productivity is reached.

Three-Dimensional Patterning

To achieve dense, repeating, three-dimensional structures on a large

13

scale, the synchronous image scan (SIS) should be used. In this tech-

nique, the contour of the desired feature is sliced into multiple layers

in the axis of the ablation z. The ablation per pulse is in the range of

0.1 to 0.2 mm. In this process, the substrate moves continuously dur-

ing pulsed laser triggering, so that coincident with each projected

laser pulse, the substrate moves by exactly one image repeat pitch.

Changing the mask synchronously with the pulsing of the excimer

laser yields the exact ablation pattern for each layer and results in the

desired three-dimensional contour on the substrate.

Figure 2.17 Nozzle array and single nozzle with flow channel.

(Source: LEXMARK)