Page 129 - Industrial Power Engineering and Applications Handbook

P. 129

Speed control loop -

6/11 0 Industrial Power Engineering and Applications Handbook

I I Torque control loop AC supply

I

.-

c

c

PID - proportional integral

derivative (a type of programming)

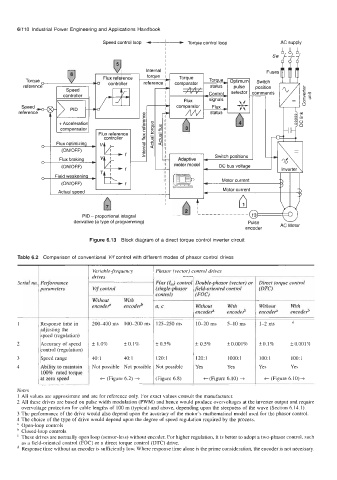

Figure 6.13 Block diagram of a direct torque control inverter circuit

Table 6.2 Comparison of conventional V/f control with different modes of phasor control drives

Variable-frequency Phasor (vector) control drives

drives

Serial no Performance Flux (I,,,) control Double-phasor (vector) or Direct torque control

parameters V/f control (single-phasor field-oriented control (DTC)

control) (FW

Without With

encode? encode# a, c Without With Without With

encode? encoderb encode? encode#

Response time in 200-400 ms 100-200 ms 125-250 ms 10-20 ms 5-10 ms 1-2 ms d

adjusting the

speed (regulation)

Accuracy of speed * 1.0% * 0.1% f 0.5% f 0.5% +0.001% *0.1% +0.001%

control (regulation)

Speed range 40: 1 40: 1 120:l 120:l 1000: 1 100: 1 1001

Ability to maintain Not possible Not possible Not possible Yes Yes Yes Yes

100% rated torque

at zero speed t (Figure 6.2) + (Figure 6.8) +(Figure 6.10) + t (Figure 6.10)+

Notes

1 All values are approximate and are for reference only. For exact values consult the manufacturer.

2 All these drives are based on pulse width modulation (PWM) and hence would produce overvoltages at the inverter output and require

overvoltage protection for cable lengths of 100 m (typical) and above, depending upon the steepness of the wave (Section 6.14.1).

3 The performance of the drive would also depend upon the accuracy of the motor’s mathematical model used for the phasor control.

4 The choice of the type of drive would depend upon the degree of speed regulation required by the process.

a Open-loop controls

Closed-loop controls

These drives are normally open loop (sensor-less) without encoder. For higher regulation, it is better to adopt a two-phasor control, such

as a field-oriented control (FOC) or a direct torque control (DTC) drive.

Response time without an encoder is sufficiently low. Where response time alone is the prime consideration, the encoder is not necessary.