Page 138 - Industrial Power Engineering and Applications Handbook

P. 138

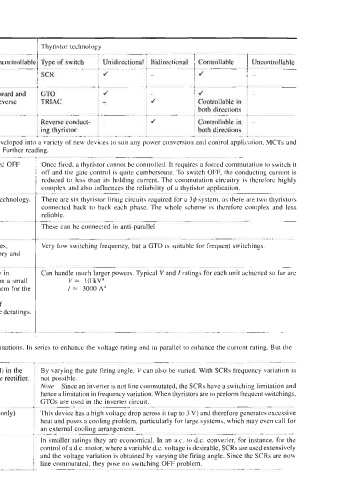

Table 6.3 A brief comparison between a transistor and basic thyristor technology

Parameters Transistor technology 1 Thyristor technology

1 As a static switch Unidirectior Bidirectional Controllable Uncontrollable

.-

~

J - J

J J

uncontrollable in reverse TRIAC - r‘ Controllable in

both directions

~ ..L-l both directions

IGBT J - Reverse conduct- J Controllable in

ing thyristor

~~~~

2 Switch OFF This calls for no switching OFF circuitry, since a transistor can be switched OFF Once fired, a thyristor cannot be controlled. It requires a forced commutation to switch it

characteristics simply by removing the base signal. off and the gate control is quite cumbersome. To switch OFF, the conductinp rnrrent is

--

>

reduced to less than its holding current. The commutation circuitry i\ therefore highly

complex and also influences the reliability of a thyristor application.

~~~

~~ ~ ~__

3 Conrrols These require only the base signal to switch ON. Thus provide a simpler technology. There are six thyristor firing circuits required for a 3$ system, as there are two thyristors

connected back to back each phase. The whole scheme is therefore complex and less

reliable.

4 For conduction ir Generally two circuits are used These can be connected in anti-parallel

both direction5

5 Switching Power MOSFETs and IGBTs can handle much higher switching frequencies, Very low switching frequency, but a GTO is suitable for frequent switchings.

frequency compared to a thyristor. In an a.c. motor control, fast switching is mandatory and

therefore transistors are preferred.

~

6 Rating (a) Can handle only moderate currents and voltages. A BJT is used mostly in Can handle much larger powers Typical V and I ratings for each unit dchieved so far dre

electronic control circuits. As they are small, hundreds can be placed on a small V= 10kVa

PCB (printed circuit board). Some manufacturers, however, also use them for the I = 3000 A”

control of small motors, say, up to 1615 HP.

(b) MOSFETs and IGBTs alone are used for power applications. Rating of

single-piece IGBT is possible up to 650 kW after considering all possible deratings.

Typical V and I ratings for a single unit achieved so far are

V= 1600Va I=2000Aa

a Subject to applicable deratings

These ratings can be enhanced bv connecting them in series-parallel combinations. In series to enhance the voltage rating and in parallel to enhance the current rating. But the

v

L

controls may not be so accurate as with a single device.

~~~ ~~ _____~

7 To vary V andf Both V andfcan be varied with the help of pulse width modulation (PWM) in the By varying the gate firing angle, V can also be varied. With SCRs frequency variation is

inverter circuit. The converter unit normally is an uncontrolled power diode rectifier. not possible.

Note Since an inverter is not line commutated, the SCRs have a switching limitation and

hence a limitation in frequency variation. When thyristors are to perform frequent qwitchings,

GTOs are used in the inverter circuit.

-

8 Heating effect Low heat dissipation due to low voltage drop across the device (up to I V only) This device has a high voltage drop across it (up to 3 V) and therefore generates excessive

heat and poses a cooling problem, particularly for large systems, which may even call for

an external cooling arrangement.

______

9 Cost factor Much more economical compared to a thyristor drive in this range In smaller ratings they are economical. In an a.c. to d.c. converter, for instance, for the

control of a d.c. motor, where a variable d.c. voltage is desirable, SCRs are used extensively

and the voltage variation is obtained by varying the firing angle. Since the SCRs are now

line commutated, they pose no switching OFF problem.