Page 160 - Industrial Power Engineering and Applications Handbook

P. 160

6/140 Industrial Power Engineering and Applications Handbook

R Y B torque, capable of picking up the load. It is also possible

that it may need a prolonged starting time not

commensurate with the thermal withstand time of the

motor or a larger starter. In such cases, it is essential to

have a minimum base or pedestal voltage as illustrated

in Figure 6.45(a). The voltage is adjusted to the lowest

possible level, so that the I,, is kept as low as possible. In

Figure 6.45(b) we illustrate a motor with a normal starting

current of 650% I, at the rated voltage. To limit this to a

maximum of 350% of I,, we have provided a base voltage

of about 350/650 or 54% of the rated voltage. The

minimum T,, is, however, matched with the load

requirement to attain the rated speed within its thermal

withstand time. For more details see Section 3.5 and

Example 7.1. The voltage is then raised so that during

the pick-up period the I,, is maintained constant at 350%,

0 until the motor reaches its rated speed.

Since it is not practical to custom build each drive, the

normal practice by manufacturers of soft starters is to

Rotor

provide a variety of motor parameters to which nearly

all motors will fit and the user may select the motor that

000

Variable V, constant fcontrol best suits the load requirements. The other advantages of

a solid-state soft start are that an unbalanced power supply

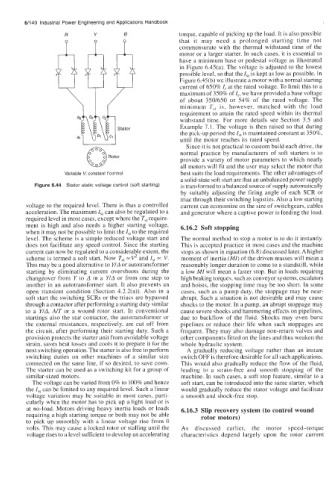

Figure 6.44 Stator static voltage control (soft starting) is transformed to a balanced source of supply automatically

by suitably adjusting the firing angle of each SCR or

triac through their switching logistics. Also a low starting

voltage to the required level. There is thus a controlled current can economize on the size of switchgears, cables

acceleration. The maximum I,, can also be regulated to a and generator where a captive power is feeding the load.

required level in most cases, except where the T,, require-

ment is high and also needs a higher starting voltage, 6.16.2 Soft stopping

when it may not be possible to limit the I,, to the required

level. The scheme is a simple reduced voltage start and The normal method to stop a motor is to do it instantly.

does not facilitate any speed control. Since the starting This is accepted practice in most cases and the machine

current can now be regulated to a considerable extent, the stops as shown in equation (6.8) discussed later. A higher

scheme is termed a soft start. Now T,, =V2 and I,, - V. moment of inertia (MI) of the driven masses will mean a

This may be a good alternative to Y/A or autotransformer reasonably longer duration to come to a standstill, while

starting by eliminating current overshoots during the a low MI will mean a faster stop. But in loads requiring

changeover from Y to A in a YlA or from one step to high braking torques, such as conveyor systems, escalators

another in an autotransformer start. It also prevents an and hoists, the stopping time may be too short. In some

open transient condition (Section 4.2.2(a)). Also in a cases, such as a pump duty, the stoppage may be near-

soft start the switching SCRs or the triacs are bypassed abrupt. Such a situation is not desirable and may cause

through a contactor after performing a starting duty similar shocks to the motor. In a pump, an abrupt stoppage may

to a YlA, AIT or a wound rotor start. In conventional cause severe shocks and hammering effects on pipelines,

startings also the star contactor, the autotransformer or due to backflow of the fluid, Shocks may even burst

the external resistances, respectively, are cut off from pipelines or reduce their life when such stoppages are

the circuit, after performing their starting duty. Such a frequent. They may also damage non-return valves and

provision protects the starter unit from avoidable voltage other components fitted on the lines and thus weaken the

strain, saves heat losses and cools it to prepare it for the whole hydraulic system.

next switching operation. The starter is also free to perform A gradually reducing voltage rather than an instant

switching duties on other machines of a similar size switch OFF is therefore desirable for all such applications.

connected on the same line, if so desired, to save costs. This would also gradually reduce the flow of the fluid,

The starter can be used as a switching kit for a group of leading to a strain-free and smooth stopping of the

similar-sized motors. machine. In such cases, a soft stop feature, similar to a

The voltage can be varied from 0% to 100% and hence soft start, can be introduced into the same starter, which

the ZSt can be limited to any required level. Such a linear would gradually reduce the stator voltage and facilitate

voltage variation may be suitable in most cases, parti- a smooth and shock-free stop.

cularly when the motor has to pick up a light load or is

at no-load. Motors driving heavy inertia loads or loads 6.16.3 Slip recovery system (to control wound

requiring a high starting torque or both may not be able rotor motors)

to pick up smoothly with a linear voltage rise from 0

volts. This may cause a locked rotor or stalling until the As discussed earlier, the motor speed-torque

voltage rises to a level sufficient to develop an accelerating characteristics depend largely upon the rotor current