Page 155 - Industrial Power Engineering and Applications Handbook

P. 155

Static controls and braking of motors 6/135

6.15.1 Illustration of energy conservation R Y B

In an industry there may be many drives that may not be

required to operate at their optimum capacity at all times.

The process requirement may require a varying utilization

of the capacity of the drive at different times. In an

induction motor, which is a constant speed prime-mover,

such a variation is conventionally achieved by throttling

the flow valves or by employing dampers.

There may be many types of the drives in an industry,

particularly when it is a process industry. The most

common drives are fan$, pumps, and compressors etc.,

Discharge -

employed for the various utilities. storage and process

activities of the plant. The plant may be chemical or a 0

petrochemical. water treatment or sewage disposal, paper

and pulp unit or even a crane or a hoist application. I

The method of speed or flow control by throttling, r

dampening (vane control) or braking, indirectly reduces

the capacity of the motor at the cost of high power loss

in the stator and slip loss in the rotor circuit, as discussed

above. These losses can now be eliminated with the

effective use of static control variable-speed drives or

fluid couplings. We will show, through the following

illustrations. the energy saving by using such controls.

Venturimeter - to measure the velocity of fluid

Probe to sense the velocity of fluid

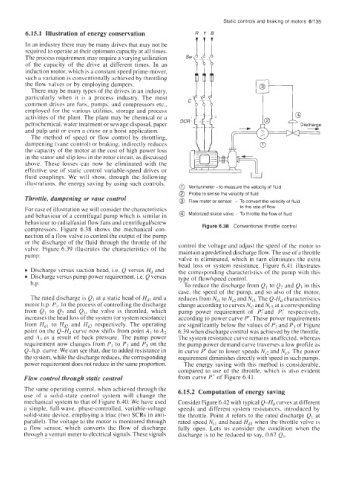

Throttle, dampening or vane control Flow meter or sensor - To convert the velocity of fluid

For ease of illustration we will consider the characteristics to the rate of flow

and behaviour of a centrifugal pump which is similar in Motorized sluice valve - To throttle the flow of fluid

behaviour to radialhxial flow fans and centrifugakrew

compressors. Figure 6.38 shows the mechanical con- Figure 6.38 Conventional throttle control

nection of a flow valve to control the output of the pump

or the discharge of the fluid through the throttle of the control the voltage and adjust the speed of the motor to

valve. Figure 6.39 illustrates the characteristics of the maintain a predefined discharge flow. The use ofa throttle

pump:

valve is eliminated, which in turn eliminates the extra

head loss or system resistance. Figure 6.41 illustrates

Dijcharge versus suction head, i.e. Q versus Hd and the corresponding characteristics of the pump with this

Discharge versus pump power requirement, Le. Q versus type of flowispeed control.

h.p. To reduce the discharge from Q, to Q2 and Q3 in this

case, the speed of the pump, and so also of the motor,

The rated discharge is Ql at a static head of Hdl and a reduces from N,, to Nr2 and Nr3. The Q-Hd characteristics

motor h.p. PI. In the process of controlling the discharge change according to curves Nrz and Nr3, at a corresponding

from Q, to Q2 and Q3, the valve is throttled, which pump power requirement of Py and P;l respectively.

inci-eases the head loss of the system (or system resistance) according to power curve P'. These power requirements

from Hdl to Hd, and Hd3 respectively. The operating are significantly below the values of P, and P, of Figure

point on the Q-Hd curve now shifts from point A, to A2 6.39 when discharge control was achieved by the throttle.

and A, as a result of back pressure. The pump power The system resistance curve remains unaffected, whereas

requirement now changes from PI to P, and P, on the the pump power demand curve traverses a low profile as

Q-h.p. curve. We can see that. due to added resistance in in curve P' due to lower speeds N,? and Nr3. The power

the system. while the discharge reduces, the corresponding requirement diminishes directly with speed in such pumps.

power requirement does not reduce in the same proportion. The energy saving with this method is considerable,

compared to use of the throttle. which is also evident

Flow control through static control from curve P' of Figure 6.4 1.

The same operating control. when achieved through the 6.15.2 Computation of energy saving

use of a solid-state control system will change the

mechanical system to that of Figure 6.40. We have used Consider Figure 6.42 with typical Q-HCI curves at different

a simple. full-wave, phase-controlled, variable-voltage speeds and different system resistances, introduced by

solid-state device, employing a triac (two SCRs in anti- the throttle. Point A refers to the rated discharge QI at

parallel). The voltage to the motor is monitored through rated speed N,, and head Hdl when the throttle valve ih

a flow sensor, which converts the flow of discharge fully open. Lets us consider the condition when the

through a venturi meter to electrical signals. These signals discharge is to be reduced to say, 0.67 QI.