Page 166 - Industrial Power Engineering and Applications Handbook

P. 166

6/146 Industrial Power Engineering and Applications Handbook

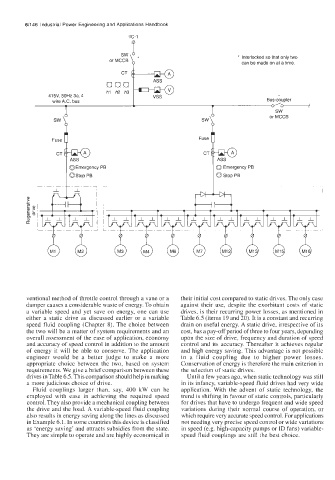

l/C-l

sw

* Interlocked so that only two

can be made on at a time.

CT

CT > >

ASS

ASS

Fuse swl Fuse swl 7’

Bus-coupler

Bus-coupler

wire A.C. bus

wire A.C. bus

sw

or MCCB

ASS

CT p@ ASS ,,F

OEmergency PB 0 Emergency PB

OStop PB 0 Stop PB

ventional method of throttle control through a vane or a their initial cost compared to static drives. The only case

damper causes a considerable waste of energy. To obtain against their use, despite the exorbitant costs of static

a variable speed and yet save on energy, one can use drives, is their recurring power losses, as mentioned in

either a static drive as discussed earlier or a variable Table 6.5 (items 19 and 20). It is a constant and recurring

speed fluid coupling (Chapter 8). The choice between drain on useful energy. A static drive, irrespective of its

the two will be a matter of system requirements and an cost, has a pay-off period of three to four years, depending

overall assessment of the ease of application, economy upon the size of drive, frequency and duration of speed

and accuracy of speed control in addition to the amount control and its accuracy. Thereafter it achieves regular

of energy it will be able to conserve. The application and high energy saving. This advantage is not possible

engineer would be a better judge to make a more in a fluid coupling due to higher power losses.

appropriate choice between the two, based on system Conservation of energy is therefore the main criterion in

requirements. We give a brier comparison between these the selection of static drives.

drives in Table 6.5. This comparison should help in making Until a few years ago, when static technology was still

a more judicious choice of drive. in its infancy, variable-speed fluid drives had very wide

Fluid couplings larger than, say, 400 kW can be application. With the advent of static technology, the

employed with ease in achieving the required speed trend is shifting in favour of static controls, particularly

control. They also provide a mechanical coupling between for drives that have to undergo frequent and wide speed

the drive and the load. A variable-speed fluid coupling variations during their normal course of operation, or

also results in energy saving along the lines as discussed which require very accurate speed control. For applications

in Example 6.1. In some countries this device is classified not needing very precise speed control or widc variations

as ‘energy saving’ and attracts subsidies from the state. in speed (e.g. high-capacity pumps or ID fans) variable-

They are simple to operate and are highly economical in speed fluid couplings are still the best choice.