Page 167 - Industrial Power Engineering and Applications Handbook

P. 167

Static controls and braking of motors 6/147

CT t-w

ASS

Interlocked so that only two

can be made on at a time.

Fuse “i Fuse 0 Fuse 0

sw$

sw$

ASS

CT CTp@

ASS

8 Emergency PB 0 Emergency PB

8 Stop PB 8 Stop PB

I

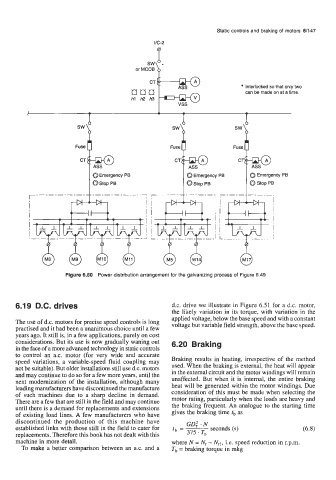

Figure 6.50 Power distribution arrangement for the galvanizing process of Figure 6.49

6.19 D.C. drives d.c. drive we illustrate in Figure 6.51 for a d.c. motor,

the likely variation in its torque, with variation in the

applied voltage, below the base speed and with a constant

The use of d.c. motors for precise speed controls is long voltage but variable field strength, above the base speed.

practised and it had been a unanimous choice until a few

years ago. It still is, in a few applications, purely on cost

considerations. But its use is now gradually waning out 6.20 Braking

in the face of a more advanced technology in static controls

to control an a.c. motor (for very wide and accurate Braking results in heating, irrespective of the method

speed variations, a variable-speed fluid coupling may used. When the braking is external, the heat will appear

not be suitable). But older installations still use d.c. motors in the external circuit and the motor windings will remain

and may continue to do so for a few more years, until the unaffected. But when it is internal, the entire braking

next modernization of the installation, although many heat will be generated within the motor windings. Due

leading manufacturers have discontinued the manufacture consideration of this must be made when selecting the

of such machines due to a sharp decline in demand. motor rating, particularly when the loads are heavy and

There are a few that are still in the field and may continue the braking frequent. An analogue to the starting time

until there is a demand for replacements and extensions

of existing load lines. A few manufacturers who have gives the braking time tb as

discontinued the production of this machine have GD: -N

established links with those still in the field to cater for tb = 7

seconds

(s)

replacements. Therefore this book has not dealt with this 375 Tb

machine in more detail. where N = I?, - Nrl, i.e. speed reduction in r.p.m.

To make a better comparison between an a.c. and a Tb = braking torque in mkg