Page 307 - Industrial Power Engineering and Applications Handbook

P. 307

la286 Industrial Power Engineering and Applications Handbook

characteristics as those of the motor, it is likely that the bi-metal

may cool faster than the motor and allow the motor to restart,

without allowing adequate time to cool. In fact, the motor windings

have a considerably higher thermal time constant than the bimetal

relays and cool more slowly than the relays. Whereas the relay will

permit rapid repeated switchings, these may not be warranted. Hand-

reset relays are thus preferred, wherever possible, to give the operator

an opportunity to investigate the causes of tripping before a restart.

Eutectic alloy relays

t These relays also possess characteristics similar to those

of a bimetallic relay and closely match the motor heating

and cooling curves. They are basically made of a low-

P melting eutectic alloy which has defined melting pro-

T

8 perties. The alloy, with specific proportions of constituent

2 metals such as tin, nickel and silver, can be made for

E different but specific melting temperatures. This property

(u

of the alloy is used in detecting the motor’s operating

conditions.

Such relays are in the form of a small tube inside

which is a loosely fitted rotatable shaft, held by a very

thin film of this alloy. The alloy senses the motor

temperature through a heater connected in series with

the motor terminals and surrounding this tube. When the

motor current exceeds the predetermined value, the alloy

10 melts and enables the shaft to rotate and actuate the

lever of the tripping mechanism.

Current (Amps.) - be adopted for all industrial controls. Some of the

Such relays are satisfactory in performance and may

1, features of these relays for use on motor starters are

given below:

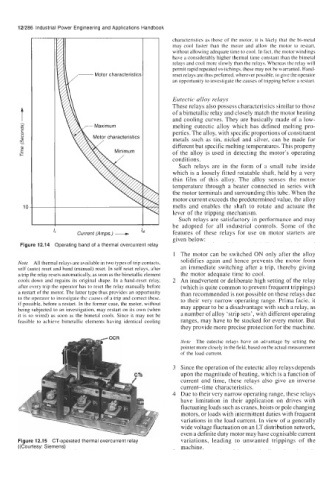

Figure 12.14 Operating band of a thermal overcurrent relay

1 The motor can be switched ON only after the alloy

solidifies again and hence prevents the motor from

Note All thermal relays are available in two types of trip contacts,

self (auto) reset and hand (manual) reset. In self reset relays, after an immediate switching after a trip, thereby giving

a trip the relay resets automatically, as soon as the bimetallic element the motor adequate time to cool.

cools down and regains its original shape. In a hand-reset relay, 2 An inadvertent or deliberate high setting of the relay

after every trip the operator has to reset the relay manually before (which is quite common to prevent frequent trippings)

a restart of the motor. The latter type thus provides an opportunity than recommended is not possible on these relays due

to the operator to investigate the causes of a trip and correct these, to their very narrow operating range. Prima facie, it

if possible, before a restart. In the former case, the motor, without may appear to be a disadvantage with such a relay, as

being subjected to an investigation, may restart on its own (when

it is so wired) as soon as the bimetal cools. Since it may not be a number of alloy ‘strip sets’, with different operating

feasible to achieve bimetallic elements having identical cooling ranges, may have to be stocked for every motor. But

they provide more precise protection for the machine.

Note The eutectic relays have an advantage by setting the

pointer more closely in the field, based on the actual measurement

of the load current.

3 Since the operation of the eutectic alloy relays depends

upon the magnitude of heating, which is a function of

current and time, these relays also give an inverse

current-time characteristics.

4 Due to their very narrow operating range, these relays

have limitation in their application on drives with

fluctuating loads such as cranes, hoists or pole changing

motors, or loads with intermittent duties with frequent

variations in the load current. In view of a generally

wide voltage fluctuation on an LT distribution network,

even a definite duty motor may have cognisable current

Figure 12.15 CT-operated thermal overcurrent relay variations, leading to unwanted trippings of the

((Courtesy: Siemens) machine.