Page 364 - Industrial Power Engineering and Applications Handbook

P. 364

Switchgear and controlgear assemblies 13/339

Main Horizontal or any other parameter. Or it can be employed in

Busbars inverter logistics, when it is being used for the control

I I I of the drive itself. Figure 13.9 illustrates a basic logical

Control

buses

scheme.

J 3 Input and output interface This is the interface

between the controlling devices and the processor.

The input/output (YO) unit receives signals from the

input devices and transmits output action signals to

the controlling devices.

Note

A separate unit is used for programming and editing (e.g. a hand-

held programmer or a computer). For on-line editing, keyboards

are used. For on-line monitoring, a PLC is interfaced with a computer

and special software.

A logical controller is thus a more effective method of

replacing the auxiliary relays and is capable of performing

many more functions instantly.

‘E c A process requiring accurate and instant speed controls

must adopt static motor controls, described in Section

6.9, and their control schemes must be activated

through programmable logic controllers (PLCs) discussed

above.

Shielding of signals

It is important to prevent the control signals from becoming

corrupted by electromagnetic interference caused by the

power circuits, particularly those carrying the motor

currents from the machine to the power-cum-control panel

housing the drive and the PLC. During each switching

sequence, the motor will draw switching currents and

develop switching voltages. Even small electrostatic

interference may lead to malfunctioning of the drive.

Shielded (screened) control cables are therefore recom-

mended for this purpose for the control panels’ internal

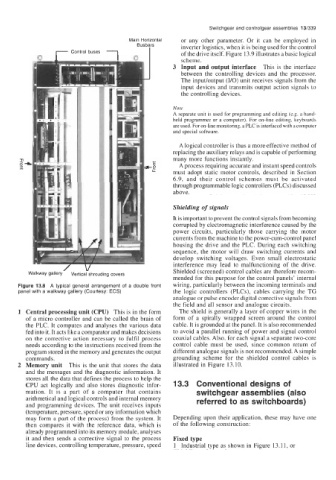

Figure 13.8 A typical general arrangement of a double front wiring, particularly between the incoming terminals and

panel with a walkway gallery (Courtesy: ECS) the logic controllers (PLCs), cables carrying the TG

analogue or pulse encoder digital corrective signals from

the field and all sensor and analogue circuits.

1 Central processing unit (CPU) This is in the form The shield is generally a layer of copper wires in the

of a micro controller and can be called the brain of form of a spirally wrapped screen around the control

the PLC. It computes and analyses the various data cable. It is grounded at the panel. It is also recommended

fed into it. It acts like a comparator and makes decisions to avoid a parallel running of power and signal control

on the corrective action necessary to fulfil process coaxial cables. Also, for each signal a separate two-core

needs according to the instructions received from the control cable must be used, since common return of

program stored in the memory and generates the output different analogue signals is not recommended. A simple

commands. grounding scheme for the shielded control cables is

2 Memory unit This is the unit that stores the data illustrated in Figure 13.10.

and the messages and the diagnostic information. It

stores all the data that defines the process to help the

CPU act logically and also stores diagnostic infor- 13.3 Conventional designs of

mation. It is a part of a computer that contains switchgear assemblies (also

arithmetical and logical controls and internal memory

and programming devices. The unit receives inputs referred to as switchboards)

(temperature, pressure, speed or any information which

may form a part of the process) from the system. It Depending upon their application, these may have one

then compares it with the reference data, which is of the following construction:

already programmed into its memory module, analyses

it and then sends a corrective signal to the process Fixed type

line devices, controlling temperature, pressure, speed 1 Industrial type as shown in Figure 13.11, or