Page 398 - Industrial Power Engineering and Applications Handbook

P. 398

13/372 Industrial Power Engineering and Applications Handbook

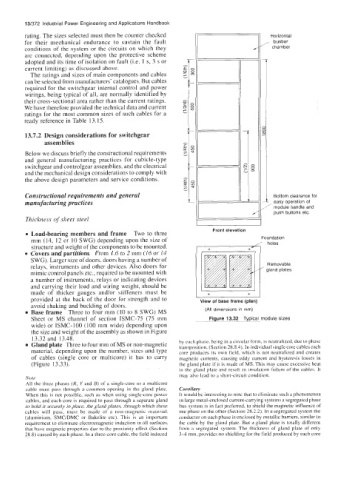

rating. The sizes selected must then be counter checked Horizontal

for their mechanical endurance to sustain the fault busbar

conditions of the system or the circuits on which they chamber

are connected, depending upon the protective scheme

adopted and its time of isolation on fault (Le. 1 s, 3 s or

current limiting) as discussed above.

The ratings and sizes of main components and cables

can be selected from manufacturers' catalogues. But cables

required for the switchgear internal control and power

wirings, being typical of all, are normally identified by

their cross-sectional area rather than the current ratings.

We have therefore provided the technical data and current

ratings for the most common sizes of such cables for a

ready reference in Table 13.15.

13.7.2 Design considerations for switchgear

assemblies

Below we discuss briefly the constructional requirements

and general manufacturing practices for cubicle-type

switchgear and controlgear assemblies, and the electrical

and the mechanical design considerations to comply with

the above design parameters and service conditions.

Constructional requirements and general Bottom clearance for

manufacturing practices easy operation of

module handle and

push buttons etc.

Thickness of sheet steel

I I

Front elevation

Load-bearing members and frame Two to three

Foundation

mm (14, 12 or 10 SWG) depending upon the size of / holes

structure and weight of the components to be mounted. +

Covers and partitions From 1.6 to 2 mm (16 or 14 +I

SWG). Larger size of doors, doors having a number of

relays, instruments and other devices. Also doors for

mimic control panels etc., required to be mounted with

a number of instruments, relays or indicating devices

and carrying their load and wiring weight, should be

made of thicker gauges and/or stiffeners must be 1' +

provided at the back of the door for strength and to View of base frame (plan)

+

avoid shaking and buckling of doors.

Base frame Three to four mm (10 to 8 SWG) MS (All dimensions in rnm)

Sheet or MS channel of section ISMC-75 (75 mm Figure 13.32 Typical module sizes

wide) or ISMC-100 (100 mm wide) depending upon

the size and weight of the assembly as shown in Figure

13.32 and 13.48.

Gland plate Three to four mm of MS or non-magnetic by each phase, being in a circular form, is ncutralized, due to phase

tranuposition, (Section 28.8.4). In individual single core cables each

material, depending upon the number, sizes and type core produces its own field, which is not neutralized and creates

of cables (single core or multicore) it has to carry magnetic currents. causing eddy current and hysteresis losses in

(Figure 13.33). the gland plate if it is made of MS. This may cause excessive heat

in the gland plate and result in insulation failure of the cables. It

may also lead to a short-circuit condition.

Note

All the three phases (R, Y and B) of a single-core or a multicore

cable must pass through a common opening in the gland plate. Corollary

a

When this is not possible, such as when using single-core powei- It would bc interesting to note that to eliminate SUC~ phenomenon

cables, and each core is required to pass through a separate gland in large metal-enclosed current-carrying systems a segregated phase

to hold it securely in place, the gland plates, through which these bus system is in fact preferred, to shield the magnetic influence of

cables will pass, must be made of a non-magnetic material one phase on the other (Section 28.2.2). In a segregated system the

(aluminium, SMC/DMC or Bakelite etc). This is an important conductor on each phase is enclosed by metallic barriers, similar to

requirement to eliminate electromagnetic induction in all surfaces the cable by the gland plate. But a gland plate is totally different

that have magnetic properties due to the proximity effect (Section from a segregated system. The thickness of gland plate of only

28.8) caused by each phase. In a three-core cable, the field induced 3-4 mm, provides no shielding for the field produced by each core