Page 400 - Industrial Power Engineering and Applications Handbook

P. 400

13/374 Industrial Power Engineering and Applications Handbook

Note with a view to providing more space within the feeder

For instrument modules, relay and control modules or control panels to achieve larger clearances between the live parts

or all power modules, where an interlock with the door is not and to lessen the chances of a fault during normal

possible or is not provided, a proper shroud or shutter must be operation, besides providing extra working space.

provided on all exposed live parts rated above 240 V. 6 The operating height of each operable mount, i.e.

the centreline of the breaker or the switch handle

To provide a folded and extensible construction to and pushbuttons or reset buttons, including the reset

allow for ease of alteration and extension of assem- probe of a protective relay on the feeder doors, is

blies at site in future, if required. recommended to be no higher than 1900 mm from

To have a modular construction with a wide choice ground level. This is an operational requirement for

of module sizes for optimum utilization of the usable ease of operation.

area in each vertical panel, which is normally 7 The height (we may consider it from the bottom

1800 mm as illustrated in Figure 13.32. The general line) of the indicating instruments such as a voltmeter

practice is to have the module sizes in the ratio of and an ammeter, which the operator may have to

1/6 (300 mm), 1/4 (450 mm), 1/3 (600 mm) and read often, is also recommended to be no higher

1/2 (900 mm), etc. Some manufacturers, however, than 2000 mm or less than 300 mm from ground

supply 1/8 (225 mm) and 1/9 (200 mm) size of level.

modules when the sizes and number of components 8 The terminals provided to receive cables to make

for a module are less and can be accommodated in external connections, may preferably be located no

such a small module size. For critical installations, less than 200 mm (at the terminal centreline) from

however, such as for a refinery or a petrochemical the gland plate.

plant or for the essential services of a power- 9 For ease of maintenance, all the busbars, horizontal

generating station or installations that are in humid or vertical, control or auxiliary, should be easily

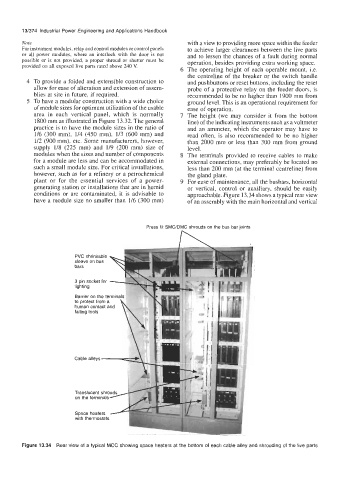

conditions or are contaminated, it is advisable to approachable. Figure 13.34 shows a typical rear view

have a module size no smaller than 1/6 (300 mm) of an assembly with the main horizontal and vertical

Press fit SMC/DMC shrouds on the bus bar joints

PVC shrinkable

sleeve on bus

bars

3 pin socket for

lighting

Barrier on the terminals

to protect from a

human contact and

falling tools

Cable alleys -

Translucent shro

on the terminals

Figure 13.34 Rear view of a typical MCC showing space heaters at the bottom of each cable alley and shrouding of the live parts