Page 97 - Industrial Process Plant Construction Estimating and Man Hour Analysis

P. 97

70 Industrial process plant construction estimating and man-hour analysis

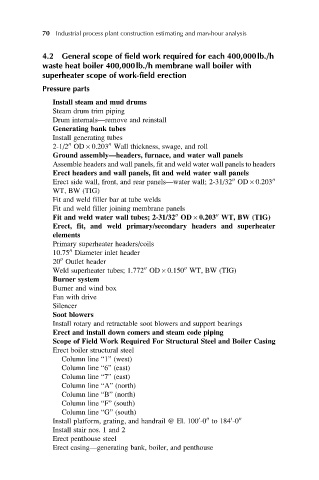

4.2 General scope of field work required for each 400,000lb./h

waste heat boiler 400,000lb./h membrane wall boiler with

superheater scope of work-field erection

Pressure parts

Install steam and mud drums

Steam drum trim piping

Drum internals—remove and reinstall

Generating bank tubes

Install generating tubes

00

00

2-1/2 OD 0.203 Wall thickness, swage, and roll

Ground assembly—headers, furnace, and water wall panels

Assemble headers and wall panels, fit and weld water wall panels to headers

Erect headers and wall panels, fit and weld water wall panels

00

Erect side wall, front, and rear panels—water wall; 2-31/32 OD 0.203 00

WT, BW (TIG)

Fit and weld filler bar at tube welds

Fit and weld filler joining membrane panels

00 00

Fit and weld water wall tubes; 2-31/32 OD 0.203 WT, BW (TIG)

Erect, fit, and weld primary/secondary headers and superheater

elements

Primary superheater headers/coils

10.75 Diameter inlet header

00

20 Outlet header

00

Weld superheater tubes; 1.772 OD 0.150 WT, BW (TIG)

00

00

Burner system

Burner and wind box

Fan with drive

Silencer

Soot blowers

Install rotary and retractable soot blowers and support bearings

Erect and install down comers and steam code piping

Scope of Field Work Required For Structural Steel and Boiler Casing

Erect boiler structural steel

Column line “1” (west)

Column line “6” (east)

Column line “7” (east)

Column line “A” (north)

Column line “B” (north)

Column line “F” (south)

Column line “G” (south)

0

0

Install platform, grating, and handrail @ El. 100 -0 to 184 -0 00

00

Install stair nos. 1 and 2

Erect penthouse steel

Erect casing—generating bank, boiler, and penthouse